Tesla's fortunes were once unpromising. The former chairman of Daimler commented in 2015 that Tesla couldn't even build a door well enough to compete with the great German car companies. seven years later, Tesla's achievements are indisputable. It has four car factories around the world, can produce nearly 2 million cars a year, sold 930,000 cars last year, and is on track to hit 1.4 million sales this year. Tesla's gross margin on the entire vehicle last year was more than 30 percent, well ahead of Toyota, the world's biggest seller (19.6 %), and ahead of rival Tesla's Azera (20.1 %), Xiaopeng (11.5 %) and Ideal (21.3 %).

One of the less observable turning points behind this change occurred in the spring of 2018, when Tesla set up a large tent to assemble the Model 3 in the empty lot of its first car factory, the Fremont, California plant. at that time Tesla was in capacity hell for not being able to deliver the Model 3 on a large scale. The big tent was derided as a "vegetable shed" and fined $29,000 for building violations.

It was also in this tent that Tesla forged the prototype of what would become the Super Factory. It explored a different set of production ideas and practices from scratch than the traditional automotive industry, which consisted of a number of self-developed automated devices, sophisticated software systems, and innovative processes. It introduced the idea of autopilot into the production line, allowing the assembly line and workstations to learn and evolve as the environment changes with materials, orders, etc.

The extreme pursuit of production efficiency and capability also explains Tesla's unique product design and the resulting high gross margins. Tesla has worked for years to reduce vehicle parts, which streamlines production steps, shortens production time, and lowers manufacturing costs.The Model 3, which began deliveries in 2017, has just over 10,000 parts, one-third the number of the Model S delivered in 2012. Before Tesla, conventional fuel cars typically had 30,000 or more parts.

Musk has a clear understanding of the importance of manufacturing capabilities. He said on Tesla's Q3 2017 earnings call that the essence of manufacturing competition is the competition for manufacturing capability - the competition for factories.

This article reviews and dismantles the history of the evolution of Tesla's factories, and the changes in product design that correspond to improved manufacturing capabilities. Competitors are already copying the innovations in Tesla's factories: both Azera and Xiaopeng, for example, are introducing one-piece die-casting processes to reduce the number of parts used to make body-in-white and shorten manufacturing times. But the more important, and harder to imitate, part is the way Tesla thinks about doing it all.

The hardest product isn't the car, it's the factory that makes it

"The hardest part wasn't designing the Model T, it was discovering the way to build cars like the Ford assembly line and building the Rouge River factory." At a 2017 earnings meeting, Musk said Tesla sees the factory as a product, a machine to build machines.

Tesla's factory quest began in 2010 when it bought the Fremont, California plant from GM and Toyota, and has since built the Nevada Battery Factory, the Shanghai Super Factory, the Berlin, Germany plant and the Austin, Texas plant.

The key turning point in Tesla's factory evolution path was the delivery of the Model 3 from 2017 to 2019. This is also the period when Tesla is in capacity hell.

When the Model 3 was launched in early 2016, Tesla had planned to start with a small volume production run and then climb to producing 5,000 units per week. But skyrocketing orders led Musk to move up Model 3 deliveries from late 2017 to July 2017, banking on building a highly automated, worker-free assembly line to ramp up production.

Prior to 2018, Musk tried to automate by sourcing off-the-shelf robotic arms, AGVs (mobile robots that move material through the production line) and other equipment with poor results.

At the California plant, engineers were still teaching robots to identify and grab different colored wires by the summer of 2017. At the Nevada battery plant, robots were far less accurate and faster than humans in lining up thousands of cells into packs. Tesla had to borrow dozens of workers from Panasonic to manually assemble the packs.In the fourth quarter of 2017, Tesla produced only 2,425 Model 3s.

The bigger challenge in automating the Model 3 is that the Model 3 changes frequently, and Musk wants the line to keep up with product iterations, which means being very flexible and able to quickly adapt to new parts and changing processes.

Traditional car companies' manufacturing methods are not up to the task. In the original assembly line, only one fixed process is repeated for each process, and the goal of automated equipment such as robotic arms is to complete a single step quickly and precisely, not to adapt to change.

In mid-2017, Musk switched gears as he began recruiting more "amateurs." Allen Chih Lun Pan, an engineer who had worked on smart driving at GM, joined Tesla's factory team at that time.Allen was 33 years old, from Taiwan, China, and favored robotics, autonomous driving, and other areas Musk called "real-world AI" (Physical AI). Pan and a group of then-newcomers were young and inexperienced in production compared to the technicians Tesla had recruited in the past who had years of experience in car production.

That's exactly what Musk sees. "You don't have the antiquated production ideas of the auto industry in your head, you can solve problems with a different perception." Musk had said when he recruited Allen.

Six months later, Musk wrote an all-hands email in April 2018 asking all R&D staff not directly related to the Model 3 to help out at the factory. Tesla started something far-reaching at this point, building the GA 4.

GA, General Assembly, is the assembly line. Previously, the California plant had three general assembly lines, of which GA 3 was responsible for the Model 3.

Unlike the first three production lines, the GA 4 is housed in a semi-permanent, enclosed "big tent." It has long been derided as a "vegetable shed" and is a testament to Tesla's overstretched production capacity.

Photo: Overhead view (top) and interior (bottom) of Tesla's California factory GA 4

But Allen tells Late Auto that it was actually in GA 4 that Tesla explored the basis for multiple superfactories that followed.

As a result of Musk's earlier email, a number of teams that had nothing to do with Model 3 production gathered at the factory, and Allen met Lukas Pankau, a 31-year-old vehicle systems architect from the University of Michigan who had joined Tesla in 2013 and was responsible for the electrical and electronic architecture of the Model X, 3, and Y.

The two engineers, with very different backgrounds and experience, began to solve production problems from a systems perspective. allen says it was a "horse race" within tesla, with different groups coming up with different solutions.

Considering that the development to mass production time for the Model 3 was drastically shortened and that production was still accompanied by frequent product iterations, Allen and Lukas decided to organize production around logistics materials and introduced the concept of self-driving technology.

Autonomous driving consists of 3 parts: perception, decision, and control, corresponding to a human driving with eyes on the road (perception), brain thinking about how to drive (decision), and hands and feet steering the vehicle (control). Projected onto production, it is sensing, learning, and automation. Sensing is done by deploying sensors on the production line to monitor the status of each work station and the relationship between adjacent work stations, where people are crowded and where they are slow; learning is based on the data collected to find room for optimization, such as integrating work stations and adjusting sequences; automation is the final part of execution, i.e. sending new actions to workers and robotic arms, AGVs and other equipment, then monitoring the new status and learn, execute, and spiral up.

The software vehicles for this solution are MOS (Material Operation System), which is the source of production by keeping track of materials, and MES (Manufacturing Execution System), which is the realization of production by mobilizing people and equipment. Allen's first six months at Tesla were spent optimizing the intelligent controllers for the AGVs and robotic arms. Together with his colleagues, he rewrote the underlying software of the robot arm, modified the controller and motors in Tesla's cars, and used them in the AGV, which was designed from scratch.

After a small test in May 2018, this solution was supported by Musk and it is called Station Control (Workstation Control).

One of the key features of Station Control is that it helps Tesla shorten the cycle time between development and production of a model. This approach to speeding up production delivery is similar to "agile development" in the software industry. Without stopping the line, when a part is missing or changes in a process on the assembly floor, the system can tell a machine or worker to skip it in tens of seconds and plug it back in at the right place later, and the line can continue to run. This breaks the traditional car company perception that production models cannot be "iterated in small steps" online.

In addition, this solution also reveals which work stations can be combined and streamlined, and which steps can be changed in sequence, which helps to improve production line speed, reduce the number of work stations, save overall quality inspection time after each process, and improve manufacturing speed.

The production line thus becomes a whole that can learn and evolve, rather than a relatively fixed process that is finely divided. allen says that when Tesla rapidly iterates its production schedule in 2018-2019, some of the GA 4 stations may adjust their tasks every half day. In a traditional car factory, production lines can only focus on one major adjustment per year.

A new experiment in the big tent helped Tesla get out of capacity hell.On July 1, 2018, Musk announced that Tesla had achieved its goal of producing 5,000 Model 3s per week. Before that summer, Tesla had laid off more than 4,000 people one by one, many of them management and R&D staff with years of experience in traditional car production. Tesla built a production system that no longer relied on them.

The production methods proven in GA 4 are being replicated in 2019 at the Shanghai Superfactory, Tesla's first car factory designed from the ground up. As previously reported by Late Auto, the Shanghai plant can increase production capacity by more than 20 percent without expanding the facility after the expansion this July. Thanks to component feature integration, volume reductions and production line iterations, the Model 3's total assembly steps have been reduced from 198 in 2017 to 43 in the first half of 2020. The race for manufacturing efficiency ends when traditional car companies have to build new plants to increase capacity, while Tesla simply upgrades its production lines.

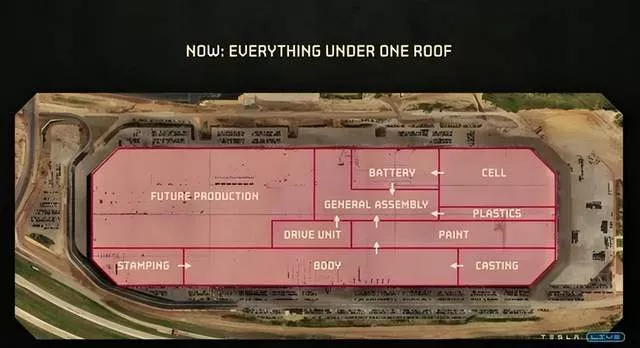

The Shanghai plant also demonstrates another vein in the evolution of Tesla's factories: the ultimate pursuit of improving the efficiency of space utilization and compressing logistics time.

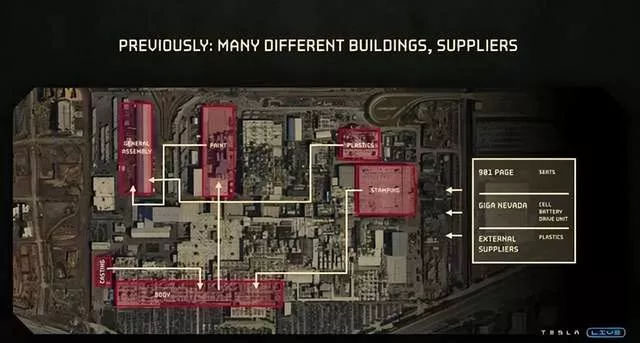

The layout of Tesla's California plant follows that of a traditional car factory: stamping, assembly, painting, and final assembly, each of the four major vehicle manufacturing processes has its own plant, scattered around the site. In the Shanghai plant, all four processes are integrated into a huge 80-hectare facility, the size of 110 standard football fields. Each part of the plant is double or multi-layered, with the upper floor used for component manufacturing and the lower floor for component transportation. Not only is space efficiency sought, but also space efficiency is sought in three dimensions.

Figure: California plant floor plan (top) and for Texas plant floor plan (bottom)

Shanghai factory has more than a hundred road entrances, when the transport parts of the container truck into the factory, will be parked directly to these road entrances, container door open, parts directly from the container into the production line, eliminating the time of unloading, parts into the warehouse, out of the warehouse, on the production line, but also eliminates a number of warehouses, the container is a temporary warehouse.

Based on the experience of the Shanghai plant, Tesla has "produced" another plant in the last two years in Berlin, Germany, and in Austin, Texas, USA. Together, they will serve Tesla's ambitious goal of producing 20 million cars a year in the future, a figure close to China's total passenger car sales last year (21.48 million).

Looking back at Tesla's journey out of capacity hell was a victory without compromise. If the idea of having production lines follow the rapid iterations of the Model 3 were abandoned, Tesla's factory could have leveraged more of its predecessor's legacy to reach the mark faster, but it insisted on doing excellence on its own terms. They're not filling a hole in the moment, they're building up long-term assets and building a deep enough moat with heavy enough R&D.

Easier to build cars

The effort to build manufacturability is not only happening inside the factory, but also at the product design stage. back in 2017 Musk said that much of Tesla's manufacturability comes from making vehicles easier to build. The way to achieve this is: fewer parts versus more software.

When development of the Model S began in 2008, Tesla was already reducing car parts and streamlining the manufacturing process.

This is on the one hand the fate of new technology products: you can't buy something off the shelf that works well and cheaply from the market.

This was before the highly vertically integrated production model of the Ford era of buying your own rubber and building your own tires gave way to a more efficient division of labor in the industry chain. By the 1980s, the major processes undertaken by car companies were fixed at stamping, welding, painting and final assembly. The flow lines started with manufactured goods from suppliers, and car companies simply bought parts "off the shelf" and put them in the car.

But when Tesla developed the Model S, that approach didn't work. What Tesla wanted, the suppliers couldn't meet. Tesla went back to vertical integration, developing and building more stuff itself. Just like when IBM started making mainframe computers in the 1940s, they developed and manufactured everything themselves, from transistors to punched components.

When designing the Model S, Tesla had to develop its own special fuses to enable faster acceleration so that the vehicle could withstand short spikes in current. Tesla also gets more deeply involved in its suppliers' development processes. in mid-2013, Tesla discovered that a component of the battery cooling system was costly and had low yields because manufacturing it required the machining and welding of two separate aluminum products. Tesla later asked Chinese cast aluminum parts supplier Sunrise to remanufacture the part through one-piece die-casting, eliminating the welding process.

Reducing parts is at the same time Musk's subjective will.

The Model S has a 17-inch touchscreen embedded in the interior that integrates the air conditioning adjustments and in-car entertainment adjustments that were originally in the car into a single screen. Dozens of buttons have been eliminated, except for physical switches that are required by law to remain, such as emergency lights.

Musk was outraged when engineers wanted to put another light switch outside the steering wheel of the Model S: "They actually wanted to get a damn switch, write software to fix it, and have the lights turn on automatically when it gets dark, simple as that."

The Model S is followed by the Model X, an SUV that began development in 2012 and is not among the "easy to build" cars. With its eagle-wing door design, the Model X is more of a work of art and extremely difficult to build.During the Q1 2017 earnings call, Musk admitted that the biggest mistake Tesla made with the Model X was designing too many complex features.

After this, the first Tesla model to shoulder the goal of mass production was the Model 3, which began development in 2015.

The Model 3 has even fewer parts. When owners sit in the Model S, they can still see the dashboard in addition to the center screen. Model 3 removes the dashboard altogether and puts all controls and car status displays, including speed, on the center screen.

The Model 3 has a "super kettle" on it that is responsible for cooling all three systems - battery, motor and air conditioning - at the same time. The Chevy Bolt EV, which came out the same year as the Model 3 and has an initial price tag of $35,000, does all of this with three separate kettles.

Building on the Model S and X, a more integral change to the Model 3 is the centralization of the electrical and electronic architecture, which uses fewer ECUs (electronic control units) and a shorter wiring harness.

In a conventional car, separate ECUs are required to control functions such as turning on lights and air conditioning, and a wiring harness is required to connect these ECUs. cars prior to Model 3 typically have around 80 ECUs, and the wiring harness can be kilometres long. For example, the new Volkswagen Golf, due out in 2019, has 70 ECUs behind more than two hundred suppliers; the Audi A8 has a harness that is more than six kilometers long.

Model 3 replaces the large number of ECU controllers in other cars with one integrated computing module and three body control modules. Each module is responsible for the data processing of multiple ECUs in its immediate area, allowing the same or even more functionality with fewer ECUs, fewer chips, and a shorter wiring harness.

In the end, the Model 3's ECU has been reduced from dozens in past cars to just over a dozen, the total number of parts has been reduced from over 30,000 in the Model S to over 10,000, and the wiring harness length has been cut in half from the Model S to just 1.5 kilometers.

The centralization of the electrical and electronic architecture requires strong software capabilities, and in traditional car companies, the software for the ECUs is written by suppliers. Tesla's reduction in the number of ECUs means redeveloping software that can control multiple functions, relying on software to ensure that less hardware is allowed to perform the same function. Tesla's software and hardware capabilities allow it to reduce its dependence on the supply chain. In times of chip shortages, engineers at traditional car companies are waiting for suppliers to send chips over, while Tesla engineers are rewriting code to replace shortages with generic chips.

The electrical and electronic architecture of the Model Y is largely the same as that of the Model 3. It has been enhanced by a combination of new technologies such as one-piece die-casting, CTC (Cell to Chassis), and 4680 cells, which have improved the efficiency of manufacturing and assembly of the body and triple electric powertrain.

The one-piece die-casting technology used in the Model Y was inspired by a zinc toy car on Musk's desk, according to Wired magazine. British toy factories used die-casting to make such toy cars in the 1950s, with workers loading molds into a casting machine, scooping spoonfuls of melted zinc alloy into the machine, and building a toy car in seconds - one casting machine that could make 7,000 cars a day.

Musk wants to build cars in this way of building toy cars, which requires finding the right materials and equipment.

In 2016, Musk-founded Space X tapped Apple's alloy expert Charles Kojman, the designer of the MacBook's metal case, to head Space X's materials engineering team. Two years later, Koeman developed an aluminum alloy material suitable for high-strength die-casting, and Space X transferred the technology to Tesla.

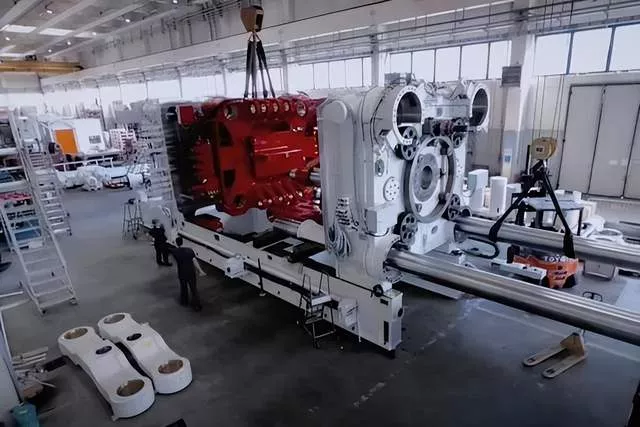

With a dedicated metal material, Tesla approached the Hong Kong-based Likin Group in 2019, which built the world's first die casting machine with 6,000 tons of clamping force (the clamping force applied to the die by the die casting machine).

In June 2020, Tesla demolished a spare workshop in its California factory to build a vaulted metal factory. Two months later, a 19.5-meter-long, 5.3-meter-high, 410-ton die-casting machine was erected here.

Photo: One-piece die-casting machine in the Tesla factory

Pour the melted aluminum alloy into this die-casting machine, and in 90 seconds, a new Model Y rear underbody rolls off the line. The original 700-800 welds on the rear underbody are reduced to 50, 70 parts are reduced to two, and body-in-white manufacturing time is reduced from 1-2 hours for the traditional process of welding various sheet metal parts into the car's steel frame to 3-5 minutes.

Tesla next plans to replace the entire lower body assembly of 370 parts with 2-3 large die castings, which will result in a 10% reduction in total vehicle weight and a 14% increase in overall vehicle range.

In addition to one-piece die-casting, Tesla has made every effort to reduce components when developing its battery technology.

While the original power cell production process was to pack the cell modules before putting them in the car, Tesla has integrated them directly into the chassis, which is CTC technology, an improvement inspired by airplane wing fuel tanks, "where the wing is the fuel tank, rather than stuffing another fuel tank in the wing." Musk said.

With CTC technology, Model Y has 370 fewer parts, 30% less weight in the lower body assembly, and 40% lower manufacturing costs.

Other car companies are copying Tesla's moves, but it's hard to copy the way it thinks

Tesla is a company where the CEO's personal will is extremely strong. Musk's way of thinking determines the way Tesla improves its manufacturing capabilities and solves other problems.

Musk practices the principle of firstness, solving things as essential elements when solving problems, finding the optimal solution from scratch, and not easily trusting what has already been done. The first sentence of the Tesla employee handbook reads: we are Tesla, we are changing the world, and we are willing to rethink everything.

In the early days of Tesla, investors thought lithium batteries were too expensive, selling for $600 per kilowatt-hour at the time, and costing up to $42,000 for a battery in a 70-kilowatt-hour electric car. Musk's way of thinking was to break down the lithium battery into lithium, cobalt, nickel and other metal materials to get a price of $82 per kilowatt-hour of lithium battery materials, which he believed could be reduced in principle by mass manufacturing. after 2010, the cost of lithium batteries fell by about 10 percent per year, with lithium batteries selling for about $170 per kilowatt-hour in 2022.

Another example is that when Tesla was building a high-current fuse in 2012, the engineers thought it couldn't be built with existing processes, but Musk thought it could be built as long as the design of the fuse didn't exceed the physical limits of the material. Tesla did end up designing and building the fuse.

Try fast fail fast and repeat the process over and over again is the methodology of the Silicon Valley software industry, and Musk is bringing this philosophy to Tesla.

Allen told Late Auto that Tesla has an internal "333" work mechanism. When an engineer has a new idea or encounters a problem, he has three days to think about the research, three days to gather the materials needed to solve the problem, and three days to make a sample or demonstrate the feasibility of the idea. After that, Tesla gives the engineer anywhere from 10-90 days to turn the idea into a demo (prototype) and then gradually iterate.

At Tesla, failures in technology development aren't really failures. One Tesla engineer said that when R&D staff asked Musk what he wanted to deliver, Musk would say, "I don't care if you succeed, what's important is to document the R&D process in its entirety."

Tesla had designed a snake robot that could charge the car early on in the development of the Model S, but the robot was too inefficient at opening the charging cover. This solution, which was abandoned at the time, was later used at the end of an unmanned forklift in Tesla's factories to give the forklift more flexibility in picking up pallets and materials. Musk runs several high-tech companies at the same time, and technology will circulate between them, and a technology that fails at Tesla may be applied in other directions as well.

Pictured: the automatic charging robot developed by Tesla

Many car companies are copying Tesla's moves. Car companies like VW are focusing on software capabilities and releasing centrally integrated electrical and electronic architectures similar to Tesla. Volvo, Xiaopeng and Azera have announced they will use one-piece die-cast technology by 2025, and Allen and Lukas founded Industrial Next in Beijing last year with plans to improve and upgrade production-line technology already proven at Tesla to other car companies. They saw a need for Chinese automakers to learn from Tesla's software-defined manufacturing.

Musk isn't resting on his laurels. Even in the face of seemingly solved problems, Tesla is considering other solutions, such as exploring unibody molding options other than one-piece die-casting, and better unibody molding options could be used in the future to build the Space X rocket.

By transforming the factory, by transforming the car, and also by polishing the factory as a product, Tesla has gone from being a layman in mass production cars to being a leader in a new generation of manufacturing methods. Tesla's most important product is not the car, but the method of making it, and the ability to invent that method.

Title photo: California factory paint shop by Rivista Automobilismo