In the world of bipedal upright walking robots, Amazon's Digit and Tesla's Optimus are about to go head-to-head.

With severe inflation in the US so far this year and increasing interest rate hikes by the Federal Reserve, more and more economists are predicting a 'recession' is on the horizon. Recessions typically spur investment in automation. According to a McKinsey survey, nearly 70% of companies have accelerated putting automation and artificial intelligence investments on the agenda.

Bezos and Musk are always the ones ahead of the curve.

Strong matchups

The 'birth' of the two major robots began last year.

Digit, a bipedal robot from robotics maker Agility, has an initial $20 million round of funding and has been tested at Ford Motor Co. Its head is a LIDAR device, and its entire body can be easily assembled.

Dry logistics means it can carry packages, unload trailers, and also walk backwards and forwards, up and down hills, across irregular terrain, turn in place or walk in a crouch.

Last year, Digit's unit cost $250,000. Ford ordered three. Ford has stuck to the "I want them all" rule for years, as they also bought Spot, a four-legged robot dog from Boston Dynamics, for $74,500. Spot is said to be hanging out in the Ford workshop.

Amazon has had warehouse robots for a long time, but not the bipedal, upright walking ones. This summer, Amazon announced a $1 billion investment in supply chain and logistics technology, and Agility's name was on the list. And the latter already received a second round of funding of $150 million in the spring.

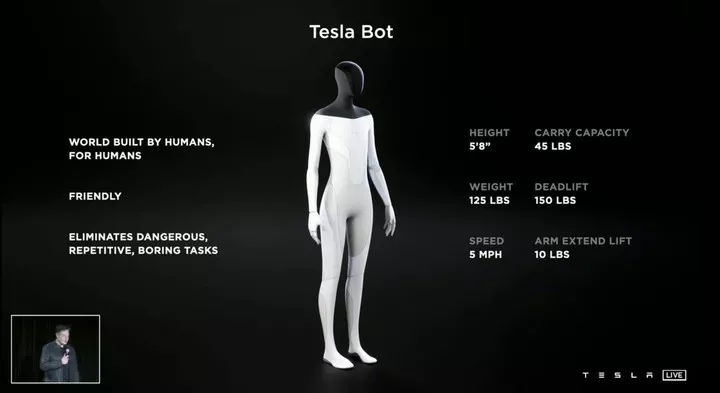

Musk announced last summer that the Tesla robot would come out this year, before it was called Optimus, which is a good name for a car + a man - that's Optimus Prime, the Autobot leader from Transformers.

'Tesla is the biggest robotics company,' Musk said, 'because our cars are semi-sensitive robots with wheels.' Just by pushing the car's self-driving capabilities and neural network learning abilities, you can make humanoid robots.

Musk described the robot as standing 5 feet 8 inches tall, weighing 125 pounds, capable of carrying 45 pounds, pulling 150 pounds hard, and moving at 5 miles per hour. He assured the audience that a human could definitely control the robot - if necessary.

Optimus prototypes could be announced around September 30, with production in 2023.

Each has its own division of labour

Amazon's investment in Agility is backed by a pressing need for automation.

The new crown epidemic, labor shortages from soaring wages, injuries to warehouse and logistics workers, and supply chain delays all require robots, says Jonathan Hurst, Agility's CTO and founder, who says robots can provide labor flexibility and allow humans to do work that requires creativity and judgment.

Compared to previous robots that could only perform a single task, Digit has the versatility to work for different types of jobs. In addition, the manufacturer has promised that Digit will soon have 'last mile' delivery capabilities, seemingly suggesting that the robot is here to knock on doors and make deliveries.

Just this April, Amazon's first warehouse union fought for a number of workers' rights. So it's 'logical' that Bezos loves robots that don't have the ability to think - they don't demand the minimum respect and the security of survival that humans do.

Likewise, Musk, who recently told his employees to get back to work and not to 'hang around' at home, is certainly a capitalist who doesn't miss any '996' opportunities.

Although the Optimus has only released some hardware figures, without specifying its purpose, it is thought to be a 'worker's life'. But not for menial work, for tertiary industry - not only as a waiter in a restaurant or shop, but also to sing and dance and chat with people, or as a nanny.

There are two other bipedal upright humanoid robots that are worth watching.

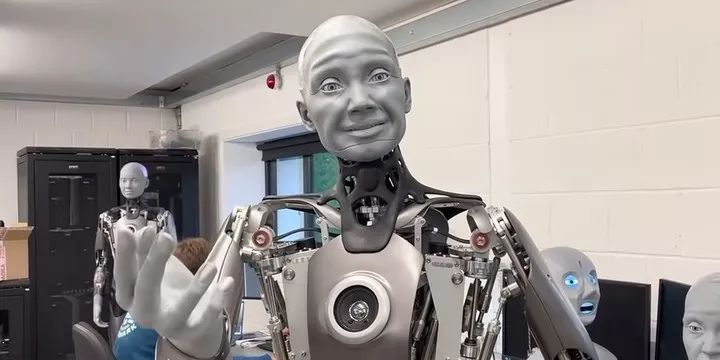

Ameca, a robot from British robotics company Engineered Arts, has also been getting a lot of attention lately. They are fully 'human-like' robots with lifelike faces and the ability to make subtle expressions, designed to interact and communicate with people. The company is ramping up production of 500,000 'entertaining' humanoid robots, and suddenly the picture is 'Blade Runner'.

Boston Dynamics is also developing Atlas, a 5-foot, 190-pound bipedal humanoid robot designed for search and rescue, which has an impressive backflip stance.

New industrial relations

Service-oriented robots for the consumer end of the market are much discussed. The code of conduct for robots is often measured in terms of morality and ethics.

However, industrial robots for the production side are rarely discussed. These robots used to be less 'human' and more automated assembly lines, and once they took on a 'human form', the discussion shifted to the moral and ethical side of the equation, with little discussion of how they work, accidents at work, or their impact on human employees.

Digit is unique in that it is both to B and to C. It works on the assembly line and will also be direct to the consumer.

The research website Reveal has conducted a survey on Amazon's working conditions. The study showed that its claim rate was higher than other practitioners in the US logistics industry. The increase in 'workplace injuries' at Amazon is due to, firstly, a significant increase in sales during the epidemic and higher demand, Amazon did not expand its staffing over-recruitment, but used multiple frequency shifts to address demand, resulting in health damage to workers; secondly, the highly automated warehouse, where the pace of work is limited by the pace of the machines, and workers are exhausted, triggering a large number of sickness accidents.

The more automated a warehouse is, the higher the worker claim rate. For example, in a warehouse, a human worker has a goal of picking 100 items an hour, and a machine picks 400. The worker's actions have to be coordinated with the machine, and the machine picks 400 items, so the human has to cooperate to complete 400 items. In this example, because of the machine, the worker has to do three times more work than he or she can handle.

Large companies see machines or robots engaged in production, as the best productivity, or productivity alternative, and workers have to adapt to the rhythm of the machines in order to complete the entire production process. This arrangement is actually not only detrimental to the workers, but actually has an impact on the social and economic structure as well. After all, it's not like robots can consume.

At the consumer level, there aren't too many scenarios where robots are currently serving. While there are delivery carts that go around in restaurants, everyone looks at them as sweepers with a tray on top.

Yet the time will come when Digit will come knocking at the door. Will we still be thinking sympathetically, "Digit, little brother, lives in an algorithm"? Maybe Digit will say indifferently, "I'm already living in an algorithm."