Glucose is the sugar absorbed by people from food. It is the "fuel" to provide power for each cell of the human body. So can glucose also power medical implants Engineers from the Massachusetts Institute of technology in the United States and the Technical University of Munich in Germany gave a positive answer. They designed a new type of glucose fuel cell, which can directly convert glucose into electricity

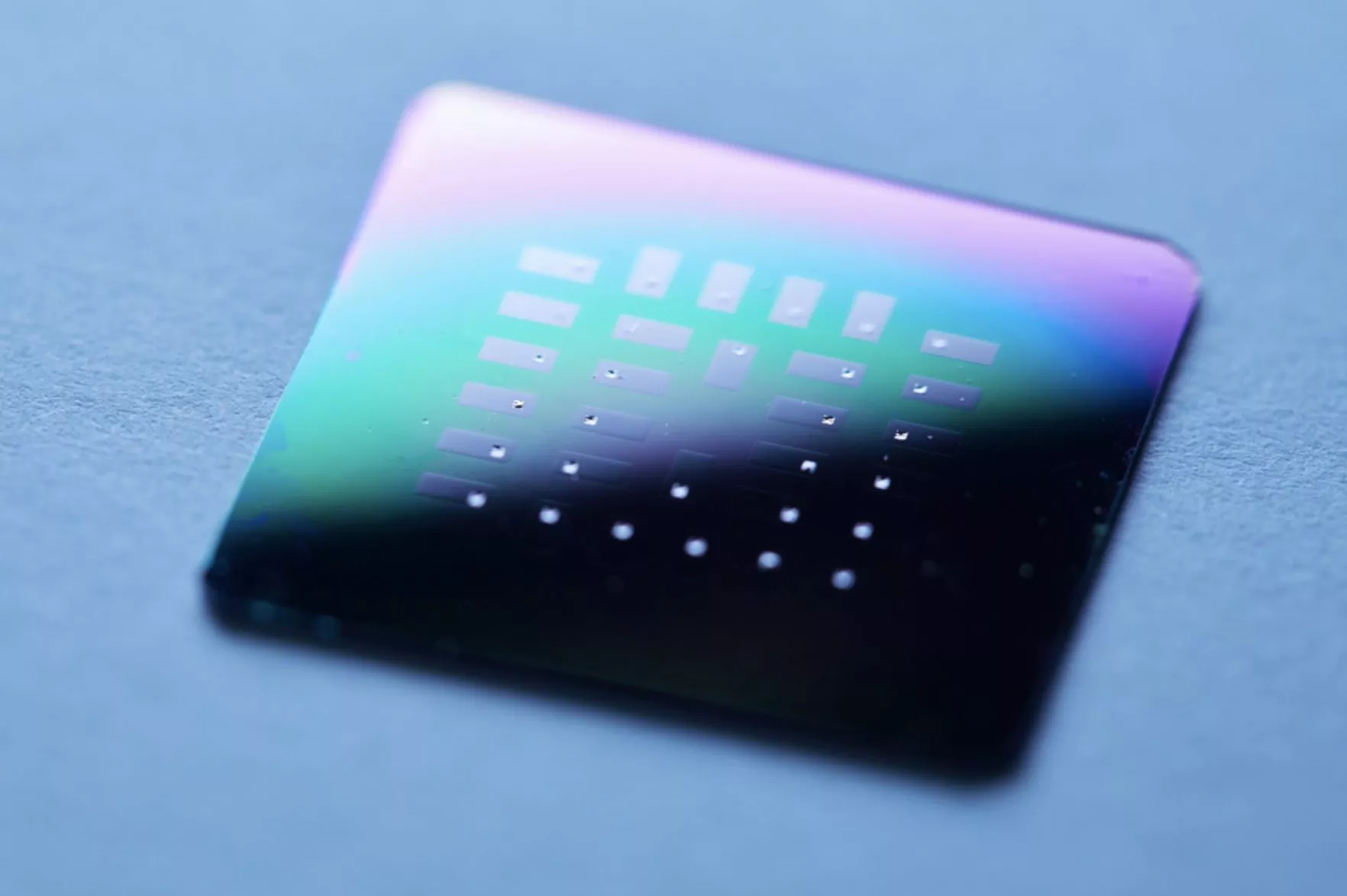

Silicon chip with 30 independent glucose micro fuel cells. Source: Advanced Materials

The device is only 400 nm thick, about 1 / 100 of the diameter of human hair. The sugar containing power supply generates about 43 micro watts of power per square centimeter, realizing the highest power density of glucose fuel cell so far.

Recently, a paper published in advanced materials pointed out that the new battery can withstand temperatures up to 600 ℃. If embedded in a medical implant, the fuel cell can remain stable during the high-temperature sterilization required by the implanted device. The core of the battery is made of ceramic, which can maintain its electrochemical properties even at high temperature and micro scale. The researchers envision that the new design can be made into an ultra thin film or coating and wrapped around the implant, using the body's rich glucose to passively power electronic devices.

In the new research, researchers designed a glucose fuel cell, whose electrolyte is made of cerium dioxide. Cerium dioxide is a ceramic material with high ionic conductivity and high mechanical strength. Therefore, it is widely used as the electrolyte of hydrogen fuel cell, which has been proved to be biocompatible.

The team sandwiched the electrolyte between an anode and a cathode made of platinum, a stable material that reacts easily with glucose. They built 150 individual glucose fuel cells on a single chip, each about 400 nanometers thin and 300 microns wide (about the width of 30 human hair). The team copied the battery pattern onto a silicon wafer, and experiments showed that the battery can be paired with common semiconductor materials. They then measured the current generated by the battery as it passed the glucose solution through each chip in a custom test station.

The team found that many batteries produce a peak voltage of about 80 mV. Given the small size of each cell, this output is already the highest power density in any existing glucose fuel cell design.

"This is the first time that proton conduction in Electroceramics is used for glucose to energy conversion, defining a new type of electrochemistry. It extends the material from hydrogen fuel cell to new and exciting glucose conversion mode," the researchers said The ceramics used in the new battery are non-toxic and cheap, and are inert to the in vivo conditions and sterilization conditions before implantation. Therefore, it opens up a new way for micro power supply for implanted sensors and other functions.