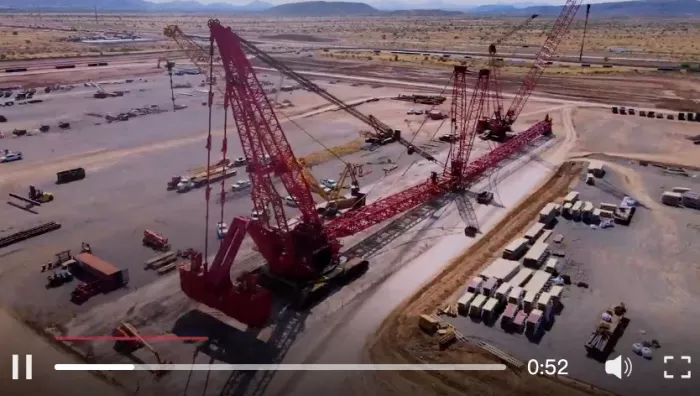

TSMC's Arizona 5nm plant, which will be put into mass production in 2024, has attracted much attention. Recently, TSMC released a short film on social media about the construction of the plant, and said that the construction of the plant is progressing steadily. Two years ago, TSMC announced that it planned to invest billions of dollars to build a 5-nanometer wafer factory in Arizona, the United States. This investment is the largest overseas direct investment in the history of Arizona.

In the short film, TSMC said that the construction of the Arizona plant was started in April 2021, and it is expected that the plant will be put into mass production in 2024, with a monthly capacity of 20000; It is expected that 2000 direct jobs and thousands of indirect jobs will be created. After the production of the Arizona plant, this plant will have the most advanced wafer manufacturing technology in the United States. TSMC customers will benefit from the benefits close to the world-class wafer foundry and industrial supply chain.

In response to the development of geopolitical situation and customer demand, TSMC began to build factories overseas last year. In addition to American factories, it has also established a jasm wafer factory in Kumamoto, Japan, in a joint venture with Sony semiconductor solutions (SSS) and Denso. It is expected to produce 22nm, 28nm, 12NM and 16nm products by the end of 2024, with a monthly capacity of 55000 pieces.

It has also been reported that TSMC may set up factories in Germany and Singapore. TSMC has said that the former is still in a very early stage of discussion, while the latter does not rule out any possibility, but there is no specific plan at present.

According to Taiwan media reports, on June 8, TSMC will hold a general meeting of shareholders to express their views on five topics, including industrial prosperity, supply and demand, global layout and competitive situation. The response of TSMC executives to overseas plant establishment will also be the focus of attention. (check / promise)