Garbage Classification Has Become More And More Popular In Our Life. Many People Will Pay Attention To Its Recycling Category When Discarding Items. If There Is Waste Glass, What Kind Does It Belong To?

Waste Glass Belongs To Recyclable Materials, Which Can Be Said To Be "given Points", But Little Is Known That The Recovery Rate Of This Recyclable Material Is Not High. Take Singapore For Example. Only 13% Of The 74000 Tons Of Glass Waste Produced In 2021 Is Recycled. Where Is The Rest Of The Waste Glass?

▲ Picture From: NTU

The Recycling Process Is Complex And The Cost Is Not Low. It Can Not Be Burned And It Is Difficult To Landfill And Degrade. Waste Glass Is A "big Problem" In Urban Waste. But A Research Team At Nanyang Technological University (NTU) In Singapore Found A Good Place For It - Hard To Recycle Waste Glass Can Be Used As A Substitute For Sand In 3D Printed Concrete.

▲ Picture From: NTU

Everyone Is Familiar With The Building Material Of Concrete. There Is An Essential Material - Sand, Which Needs To Be Used To Adjust The Proportion To Optimize The Mix Proportion Of Various Materials. The Reason For Choosing Glass Instead Of Sand Is Also Simple: Glass Is Made Of Silica, Which Is The Main Component Of Sand.

▲ Picture From: Unsplash

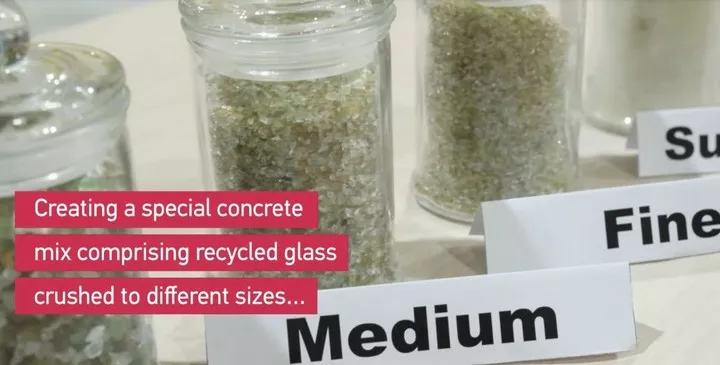

The Researchers Crushed The Glass Waste Into Five Different Sizes Of Fragments: Coarse, Medium, Fine, Ultra-fine And Dusty, Which Were Used To Replace The Sand And Gravel Commonly Used As Concrete Aggregate. In Order To Save Cement And Improve The Strength Of Concrete, It Is Necessary To Mix Particles Of Different Sizes To Minimize The Gap Between Sand Particles.

▲ Picture From: NTU

Using This "specially Formulated" Mixture Containing Recycled Glass, The Researchers Successfully Created A 40 Cm High Concrete Object With A 3D Printer. The Poured Concrete Has No Deformation Or Collapse Before Curing, And The Fluidity Can Easily Flow Through The Printer Nozzle.

▲ Picture From: NTU

More Importantly, The Strength Of This "special" Concrete After Curing Is Similar To That Of Traditional Sand Containing Concrete.

It Is Worth Mentioning That, In Addition To 3D Printing Concrete, A Research Team At Deakin University In Australia Also Used Glass Waste Instead Of Sand To Create Glass Based Polymer Concrete With Non 3D Printing Structure.

▲ Glass Based Polymer Concrete Of Deakin University, Photo From: Deakin University

These Are Enough To Show That Whether 3D Printing Or Using Traditional Methods, Glass Waste Can Be Used To Replace Sand To Make Concrete, And The Replacement Proportion Can Even Reach 100%.

Using Waste Glass Instead Of Sand To Make Concrete Is For Glass And Sand. The Development Of Cities Means A Great Increase In The Demand For Building Materials, And River Sand Is Usually Used In The Construction Of Concrete, Which Leads To The Fact That The Amount Of Sand Mining Is Far From Meeting The Increasing Demand.

▲ Picture From: NTU

Using Glass Waste Instead Of Sand To Make Concrete Can Not Only Make So Many Waste Glass That Can Not Be Placed Anywhere Have A "place To Use", But Also Slightly Overcome The "sand Dilemma" Faced By Making Concrete. This Method Undoubtedly Has Broad Prospects.

In Fact, There Is Also An Unexpected Benefit, Because Glass Does Not Absorb Water As Much As Sand, So It Requires Less Water To Make Concrete In This Way.

People Always Say That "garbage Is A Resource Placed In The Wrong Place". This Is Exactly The Case With Waste Glass. When They Are Put From The Garbage Into The Concrete, They Become Building Materials. It Not Only Makes Use Of Waste, But Also Saves Resources, Which Can Be Said To Kill More With One Stone.