In the future, people may be able to wrap milk tea with A4 paper with the help of coating. According to a study published on the 13th in the Journal of industrial and Engineering Chemistry published by the American Chemical Society, researchers at the University of Tokyo in Japan have found a simple, economical and efficient method for the first time to "endow" some characteristics of plastics to relatively sustainable paper materials. A coating called choetsu can not only make the paper waterproof, but also maintain its elasticity and biodegradability.

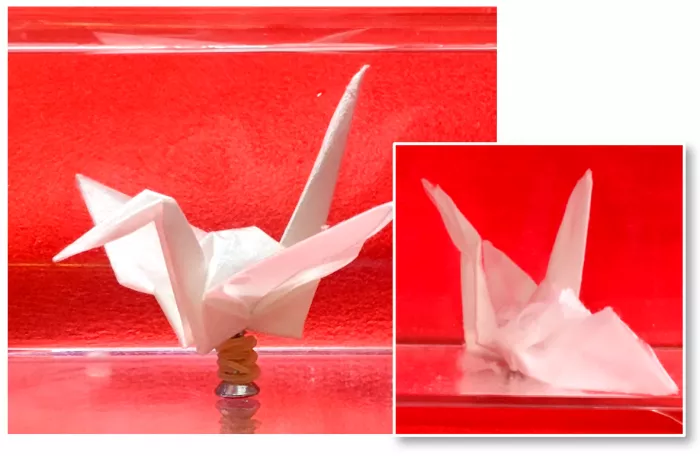

The classic paper folding crane made of paper is coated with choetsu (left) and Uncoated (right). When immersed in water, the coated crane maintains its shape, while the uncoated crane is quickly soaked in water and begins to decompose. Source: hiroi Quaner et al

"In my opinion, the main problem with plastic materials is that they cannot degrade quickly and safely." Hiroi Quanji, a professor at the Institute of solid state physics at the University of Tokyo, said that although materials such as paper can be safely degraded, they can not meet the wide application of plastic materials. Now, the new method can give paper some good characteristics from plastics, but it will not have any adverse impact on the environment.

Choetsu is a combination of materials. When applied to paper, it will spontaneously produce a strong waterproof film when it comes into contact with moisture in the air. The coating consists of safe and low-cost chemicals, mainly methyltrimethoxysilane, some isopropanol and a small amount of tetraisopropyl titanate. Structures made of paper, such as food containers, are sprayed or immersed in this coating and dried at room temperature. Once dried, a thin layer of silica containing methyl will form on the cellulose constituting the paper, providing strong waterproof performance.

In addition, the reaction in the coating process will automatically generate a layer of titanium dioxide nanoparticles, resulting in dirt and bacterial rejection characteristics, which can protect the coated articles for a long time. Over time, all chemicals involved in the coating will decompose into harmless substances, such as carbon, water and sandy silicon.

Hiroi said he hopes to apply this method to other types of materials in the future. At the same time, the liquid composition can also be adjusted for other materials, so as to create an antifouling and mildew resistant coating, which can be applied to glass, ceramics and even other plastics.