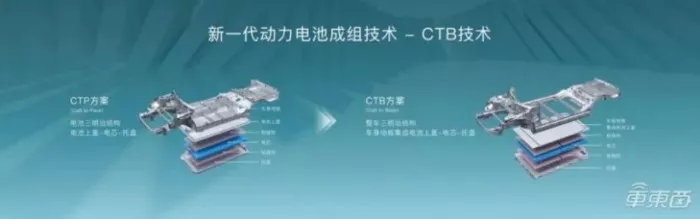

Among the new energy vehicles in the head, Tesla explained the CTC technology as early as the battery day activity in 2020, and believed that this technology can save 370 body parts and reduce the body weight by 10%, while BYD, another player in the head, also released the CTB technology this year (still CTC technology in essence).

What is the difference between electric vehicle enterprises and CTC technology?

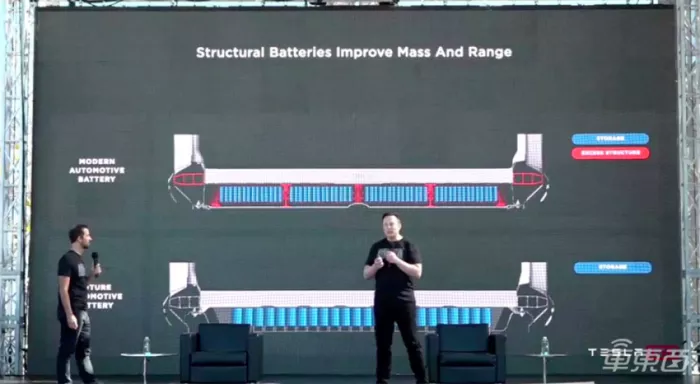

▲ Tesla shows CTC Technology

Ningde times, a leading player in the power battery industry, is also actively developing CTC technology. Caijianyong, former general manager of Bu intelligent vehicle control field, Huawei's intelligent vehicle solution, joined Ningde times and will spare no effort to promote the CTC battery chassis integration business.

In April, the domestic new car manufacturing enterprise zero race officially announced its CTC technology, which can increase the endurance of its first car C01 to more than 700 km.

In addition, Nezha, Volkswagen, Volvo and other car companies will make efforts in CTC technology. Nezha has made it clear that it will launch this product next year.

From the actions of these car companies, *ctc technology has undoubtedly become one of the hottest topics in the field of power batteries this year *.

With the development of new energy vehicles, the development of power batteries has reached the ceiling, and there is an urgent need to break the situation. In terms of chemical materials, the ceiling of ternary lithium batteries is gradually emerging, while solid-state batteries still have a long way to go from mass production.

In this case, new energy automobile industry giants such as Tesla and BYD and power battery giants such as Ningde times have begun to make layout in battery packaging technology.

Judging from the actions of many automobile enterprises and battery enterprises, the leading automobile enterprises in the field of new energy vehicles have joined the CTC army. In the foreseeable future, this technology may become the main power battery packaging technology.

So, what are the main difficulties of CTC technology? What are the main technology paths? What are the main paths adopted by the car companies that have been released so far?

- it is also difficult to redesign the integrated battery for the body structure

First of all, let's have a brief introduction to CTC technology. Its full name is cell to chassis, that is, cell to chassis . Literally, it means that the battery cell is directly placed in the vehicle chassis, which is different from the previous design that the chassis is separated from the battery pack.

The main reason for this is to improve the energy density of the battery by improving the space utilization. After the battery cells are directly integrated into the chassis, a lot of materials can be saved, and the volume of the installable battery cells can be expanded accordingly. By adding more battery cells and increasing the volume energy density, car enterprises can achieve longer endurance performance.

On the other hand, the cost of the power battery is reduced due to the saving of more materials.

From the above description, CTC technology does have many advantages, but the fact that there is no large-scale mass production also shows that this technology is still difficult .

On the whole, there are many core technical points in CTC technology.

First of all, cell to chassis means that the traditional vehicle chassis structure needs to be changed.

A body engineer told the car that in order to save costs, most car companies would take battery packs directly from suppliers and then design the body structure according to the battery packs.

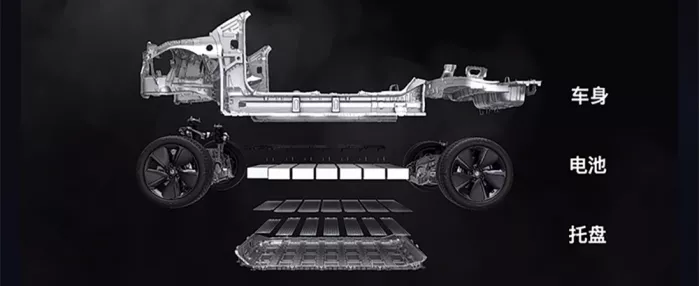

*The body, battery pack and chassis form a sandwich structure *. The battery pack is between the body and chassis, that is, the battery pack is always protected by the body structure and will not directly withstand external impact.

The CTC technology integrates the battery cells directly into the vehicle chassis. The battery pack becomes a part of the chassis. The inner floor of the carriage acts as the upper cover of the traditional battery pack. The battery cells and the lower tray are stuffed into the vehicle body, making the battery pack one of the stress structures of the vehicle body.

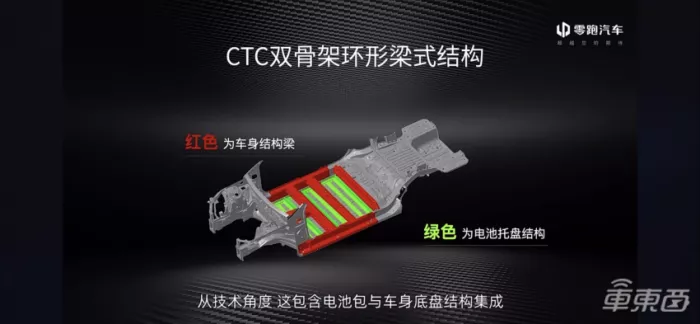

▲ CTC technology released by zero running car

*This makes the traditional mode of separate design of body and battery pack no longer applicable *. Body designers should consider the layout of chassis cells when designing the body from the beginning, which is a big test for most body designers.

On the other hand, CTC technology also has a certain impact on the flexibility of body design. For large-scale automobile enterprises, they will design a general automobile platform, which can extend a variety of models, and the changes in battery are lengthening and shortening.

However, after the adoption of CTC technology, when the body structure changes, the battery structure of the chassis will also change, resulting in an increase in the design cost.

More importantly, the cost and technical difficulty of maintenance will also increase after the battery cell is integrated with the body chassis.

From this point of view, one of the most critical technologies of CTC is the design of body structure .

Then let's focus on the battery pack itself. A very important element of CTC technology is to completely eliminate the modules and packs and directly integrate the battery cells into the chassis.

▲ Tesla CTC Technology

This also means that the electric core needs to be directly laid in the vehicle chassis. Without the protection of the module and pack structure, the electric core needs to be insulated and supported.

In addition to some designs necessary for the battery cell, the battery thermal management and other aspects also need to be updated.

The cells and cells are directly arranged together, which means that once a cell loses heat, it is easy to conduct to the adjacent cells, resulting in the thermal loss of the whole battery.

When designing, it is necessary to consider exactly where the water cooling plate is placed and how to design the pressure relief valve. These issues are directly related to the safety of vehicles and passengers, so the design in this regard should not be sloppy* The BMS design of the whole battery pack is also very important *.

On the whole, if you want to adopt CTC technology, it will have a certain impact on the structural design of the car body and the design of the battery pack. These main difficulties have become the most critical areas of CTC technology.

- both approaches have reached the night before mass production

At present, CTC technology is relatively new, and only a few car companies have shown their own solutions and products, and most car companies have not shown their products yet.

From the released products, CTC technology has two main forms. One is the method adopted by many car companies at present - directly integrate the battery into the vehicle chassis .

This approach is a bit close to the development idea in the field of smart phones: from the beginning, the battery is removable to the battery integrated design .

Specifically, the car companies have directly cancelled the upper plate structure of the battery pack, or used the inner bottom plate of the vehicle as the upper plate structure of the battery pack, and then placed the battery cells on the tray, combining the tray and the inner bottom plate of the car body to form a new car body structure.

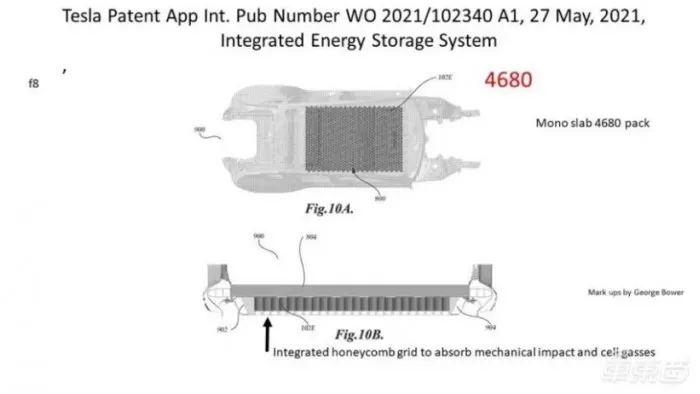

▲ screenshot of Tesla battery patent

The seats of the vehicle can be directly installed above the battery pack to further expand the space structure of the vehicle body, and more batteries can be added to the battery layout, so the endurance can be improved.

So how does this approach address the technical challenges? In this regard, different car companies have different strategies. In terms of the body structure, Tesla has adopted the front and rear integrated die-casting technology to change the body structure. The front and rear two large parts can be directly spliced into the vehicle chassis. The space of the chassis can be reserved in advance to prepare for cell integration.

And BYD has also adopted the brand-new model platform e3.0**. Although it is not clear how BYD does it, it will certainly adjust the body structure in the new model platform.

In terms of heat dissipation, the water-cooled plate is still mostly used for heat dissipation. In Tesla's scheme, the water-cooled plate is placed directly above the battery cell, so that the heat of the battery cell will not be uploaded to the cockpit, while the pressure relief valve of the battery pack is under the battery cell, further ensuring the safety of the battery pack. Low density glue is used between the cells to reduce the risk of heat conduction between each other.

*In the Zero run scheme, a water-cooled plate and a heat insulation layer * are used under the battery cell, while a heat insulation layer is also used above the battery cell to prevent heat from rising to the cabin.

The other is the sliding plate chassis, which also covers CTC technology and wire control technology. It completely decouples the driving system and steering system of the vehicle chassis from the passenger compartment of the vehicle, and the chassis and the vehicle body are directly independent.

The car has watched the skateboard chassis designed by Youpao technology before. Through the remote control device, the vehicle chassis can freely complete a series of commands for forward and backward, and even automatic parking.

▲ Youpao technology up super chassis

This design method is similar to the non load-bearing structure in the era of fuel vehicles, with separate chassis and body design. But the difference is that this kind of skateboard chassis is more powerful, which can be said to be the soul of the vehicle.

As long as the chassis and body reach an agreed communication protocol, various models can be manufactured according to the skateboard chassis.

Thanks to the previous experience in the design of non load-bearing body structure, it does not need to spend too much energy on the redesign of the body after using the skateboard floor, and it can almost copy the previous non load-bearing body design scheme.

The battery pack structure and heat dissipation are particularly critical to the skateboard chassis. Peter Rawlinson, CEO and CTO of lucid, once explained how to protect and heat the skateboard chassis. He believes that the combination of the battery pack and the vehicle body shell can increase the structural stiffness of the vehicle, make the vehicle easier to operate, stabilize the central structure of the rear collision buffer zone, absorb energy, protect passengers from collision, and protect the battery.

In lucid's scheme, the cell is basically installed upside down, the battery radiates heat downward, and there is an additional layer of coolant.

However, at present, this technology has not achieved large-scale mass production, and the leading enterprises rivian and lucid are currently in the stage of capacity climbing, and have failed to complete large-scale delivery. In addition, other skateboard chassis enterprises have not achieved mass production.

▲ electric r1t pickup

On the whole, the direct integration of the battery into the chassis has become a common choice between car companies . Therefore, at present, the number of automobile enterprises that make efforts in CTC technology has also increased significantly.

Tesla, BYD and zerorun have released their own CTC schemes. Volkswagen and Volvo have also put forward their CTC schemes in 2021 and will put them into mass production in the future. Nezha also said at its battery sharing meeting that it will launch CTC technology next year.

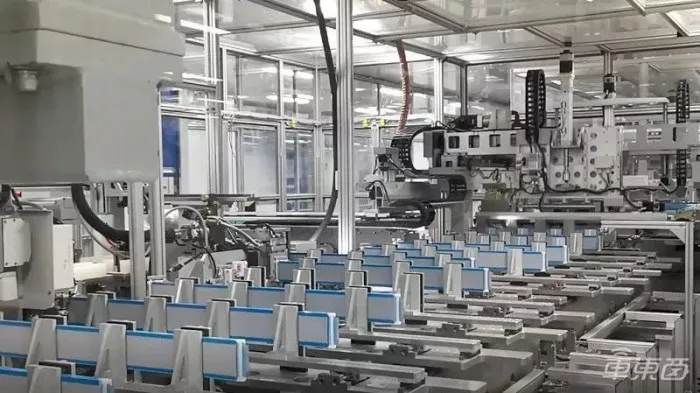

In terms of battery enterprises, Ningde times proposed to develop CTC technology as early as August 2020. At present, it has also welcomed the joining of Bu executives of Huawei cars. Its mass-produced products should also appear soon.

In addition, other power battery enterprises such as honeycomb energy have also accelerated the layout in this regard.

At present, CTC technology may really become an important breakthrough in battery technology, which is very important for alleviating endurance anxiety and improving battery safety.

- the three auto companies have released similar main strategies

Although many auto companies have announced their CTC plans, at this stage, only Tesla, BYD and zero race have released their products, and there are many product maps.

From the aspect of product design, the three auto companies chose the first form above and directly adopted CTC technology. However, from the perspective of design details, there are also some differences in the strategies of the three enterprises.

The following is a comparison between Tesla, BYD and Zero run in terms of structure, cell integration and manufacturing process.

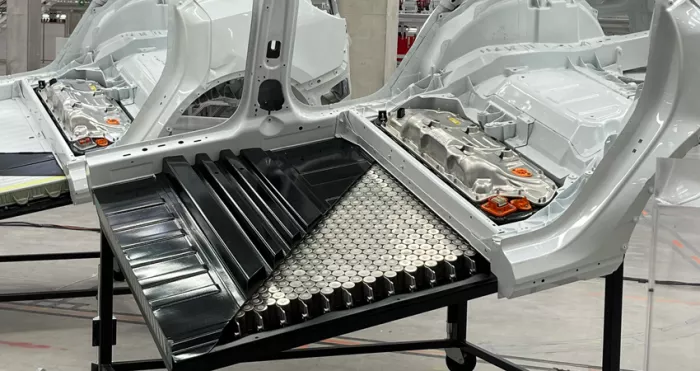

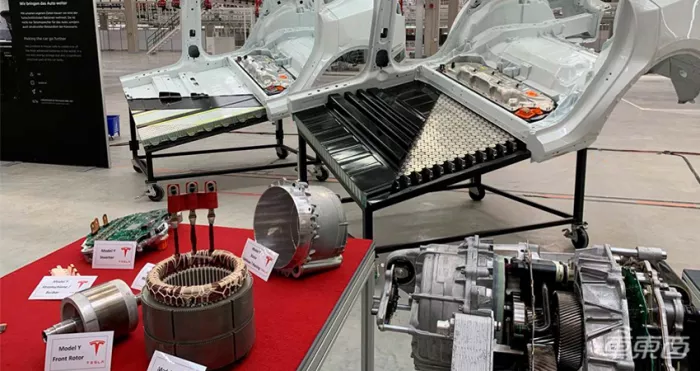

From the perspective of structure, Tesla may be the most radical enterprise to make changes. According to the pictures from Tesla's Berlin factory and Texas factory, its CTC technology has completely connected the battery pack with the car.

▲ Tesla seat is directly installed on the battery

There is a beam above the battery pack, the front seats are directly installed on the beam, and the fixed structure of the rear row has nothing to do with the battery pack.

In this way, the downward pressure of the two front seats is directly borne by the battery pack, and the force of the feet of the front and rear passengers is also directly borne by the battery pack.

BYD and Zero run are relatively close. According to the pictures displayed at the press conference, the CTC scheme still retains the skeleton ring beam structure on the body on the original vehicle chassis.

▲ zero running CTC technology display

The upper plate of the battery pack is directly welded with the structural beam of the chassis, which is equivalent to both the bottom plate of the carriage and the upper plate structure of the battery . The vehicle seat is directly installed on the structural beam of the vehicle body. The battery pack only bears the power of the front and rear rows of passengers' footstep space.

From the exposed pictures, the design of BYD is very similar to that of Zero run. It also combines the bottom plate of the carriage and the upper plate structure of the battery, and the design scheme of the seat is also similar.

▲ BYD CTB Technology

Although the plans of Tesla, BYD and zero race are slightly different, there is no good or bad difference between these plans .

In these schemes, the passengers in the car are only separated from the battery cell by a battery upper plate structure. Therefore, the three car companies need to make a buffer design to avoid the car owners' direct pressure on the battery cell when they step on the floor, so as to reduce unnecessary trouble.

On the other hand, it is also very necessary to add thermal insulation material above the cell, so as to prevent the heat from being transferred to the passenger compartment at the first time after thermal runaway.

In addition to the body structure, cell integration is also a very key point, which is also the biggest difference among the three car companies .

From Tesla's point of view, it has been very clear about Tesla's cell. Whether it is the pictures displayed by the Berlin factory or the Texas factory, its CTC technology is closely connected with the 4680 cell.

▲ Tesla chassis is full of 4680 batteries

Tesla mainly arranges and combines 4680 cells on the chassis. There is no module inside. At a glance, it is full of 4680 cells. According to the pictures shown by Tesla, there are about 34 columns in a column, which are divided into 24 columns, with water-cooled panels in the middle for heat dissipation.

From this point of view, Tesla has truly implemented cell to chassis.

At present, BYD has not exposed the internal picture of CTC battery, but according to the previous design of dolphin battery pack, it can be speculated that its practice is similar to that of Tesla, which adopts the method of direct integration of blade battery into the chassis.

Unlike Tesla's cylindrical battery, BYD's blade battery is longer, almost across the body, and has canceled the module in the CTP era. At present, it is likely to directly use the blade battery to integrate into the chassis.

▲ BYD blade battery

The Zero run approach is slightly different. From the structure diagram, the CTC with zero running adopts the mode of integrating modules into the chassis, and adopts seven large modules. As a result, the number of spare parts saved is limited, and the space utilization rate is not the best.

So from this point of view, the Zero run strategy is more like MTC than CTC.

▲ Zero run CTC technology still has battery module

However, this can not be separated from Zero run automobile's failure to participate in the development of battery cells. BYD has been using its own battery cells. Tesla has also been actively producing 4680 battery cells recently. The advantage of self-produced battery cells is that the two companies can develop CTC according to their own battery standards in advance .

For Zero run, there is no ability to produce its own battery cells at present. It is mainly to purchase battery cells from suppliers. Direct integration of modules is more efficient and convenient.

From the perspective of manufacturing process, Tesla has innovated the manufacturing process and adopted the front and rear integrated die-casting technology, which complements the CTC technology and can manufacture the car body more efficiently. However, BYD and zero race have not made much change in the car body manufacturing process, and it is possible to introduce the integrated die-casting technology in the future.

On the whole, the CTC of Tesla and BYD are more thorough both in terms of structure and overall design. Zero run does not have the ability of cell integration, and there is still much room for improvement.

However, these three auto companies have already taken a key step, and I believe that more auto companies will join the ranks in the future.

- conclusion: battery technology innovation is imminent

In the current field of new energy vehicles, the power battery is still a very important component, and even determines the lower limit of an electric vehicle. However, at present, its development has encountered a certain bottleneck, and it has been unable to further break through.

Car companies and battery cars are mainly looking for solutions from two aspects. First, starting from the chemical system, they are developing new chemical systems and solid-state batteries, but the progress is not obvious.

Another method is to insert more cells per unit volume by improving the packaging process. On this path, car enterprises and battery enterprises have launched CTP technology, namely cell to pack, which cancels battery modules; At this stage, CTC technology is introduced.

However, this is not enough for the current battery industry. In the case of soaring raw material prices, it is also necessary to promote the innovation of battery technology.