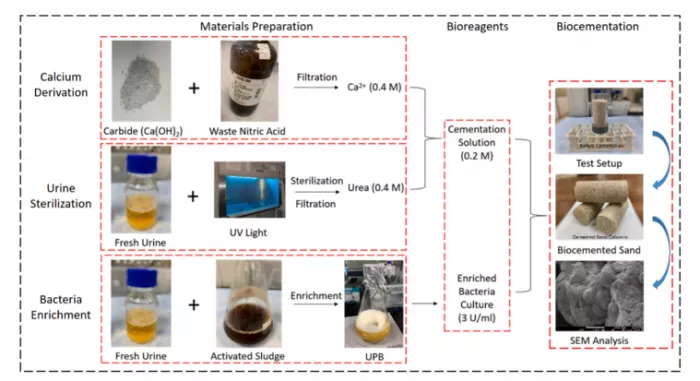

The production of traditional Portland cement is a major source of greenhouse gas emissions because raw materials must be heated to high temperatures. However, a new kind of biological cement is not like this. It also absorbs waste The biological cement developed by researchers at Nanyang Technological University in Singapore consists of two main substances - Industrial carbonized sludge, which is a by-product of acetylene gas production; And urea, which is extracted from the urine of mammals such as humans, cattle or pigs

Sludge is initially treated with an acid to produce soluble calcium. Urea is then added to the calcium to form a so-called cementation solution. Special bacteria are then added to the solution, where they break down urea to form carbonate ions.

Next, in a process called "microbial induced calcite precipitation", these carbonate ions react with soluble calcium ions to form hard solid calcium carbonate. When the mixture is combined with sand or soil, the reaction is in progress, and calcium carbonate binds the sand / soil particles together and fills the space between them.

The result is a solid block of material that prevents water from seeping out and is the same color as the original sand or soil. More importantly, the whole production process is carried out at room temperature.

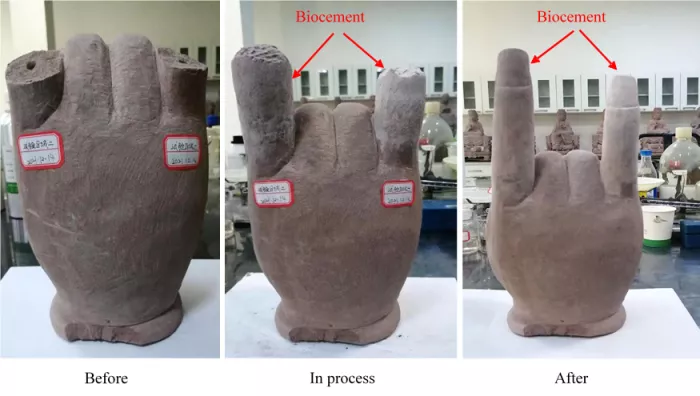

The application of sand on the ground (including the construction of hard shells on the beach) to reduce the possible erosion of biological shells on the construction site. The material has even been used to fill cracks and rebuild parts of damaged stone monuments.

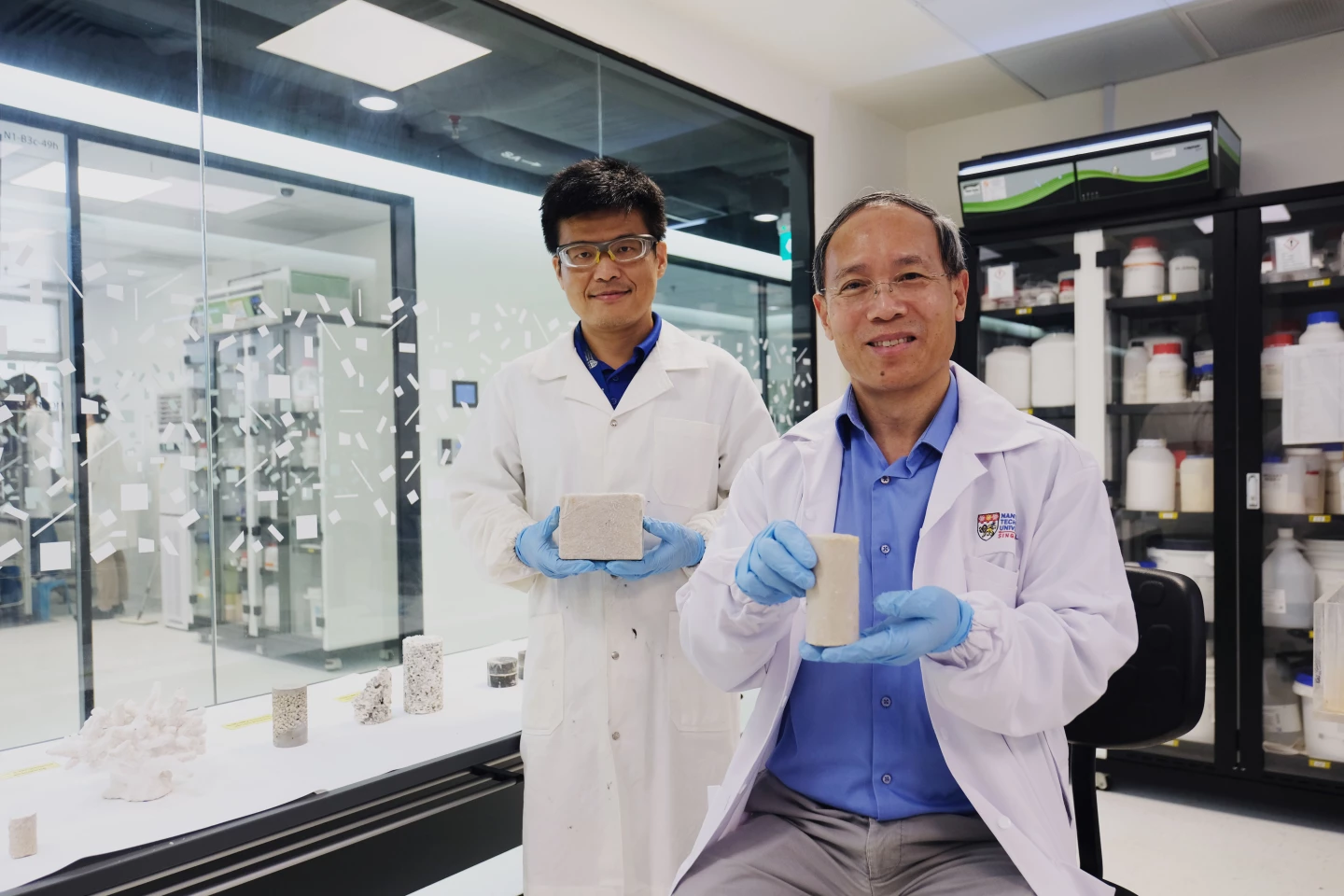

Scientists recently published in Environmental Chemical Engineering 》A paper on the study, led by Professor Chu Jian and Dr. Yang Yang, was published in the journal.