When combined with liquid gallium, the amount of platinum required is small enough to greatly expand the earth's reserves of this precious metal. At the same time, it is possible to provide more sustainable solutions for carbon dioxide emission reduction, ammonia synthesis in fertilizer production and the creation of green fuel cells, as well as many other possible applications in the chemical industry.

When it comes to the potential of these catalytic systems, these platinum focused discoveries are just a drop in the ocean of liquid metals. By extending this approach, there may be more than 1000 possible combinations of elements for more than 1000 different reactions. The results will be published in the journal Nature chemistry on Monday, June 6, 2022.

Platinum is very effective as a catalyst (trigger of chemical reaction), but it is not widely used in industrial scale because of its high price. Most catalytic systems involving platinum also operate at high sustained energy costs. Generally, the melting point of platinum is 1768 ℃ (3215 ℉). When it is used for industrial purposes in a solid state, about 10% platinum is required in the carbon based catalytic system.

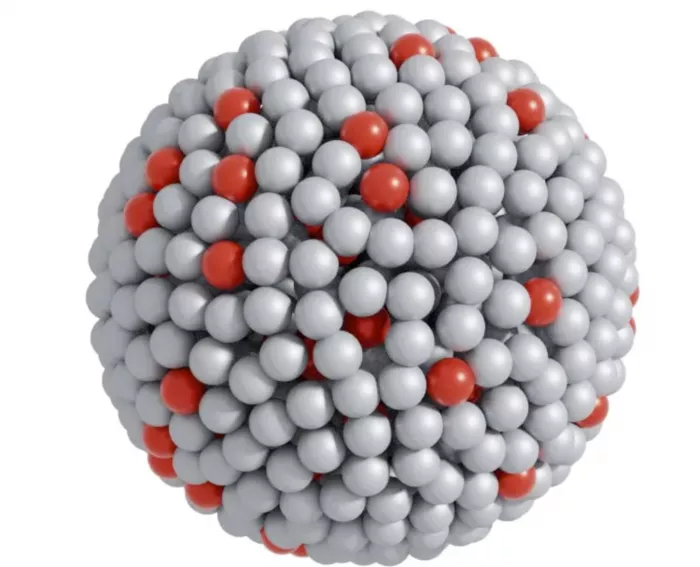

However, scientists at the University of New South Wales (UNSW) Sydney and the Royal Melbourne Institute of technology have found a way to use a very small amount of platinum to produce a powerful reaction without expensive energy costs, which may change in the future. The team, including members of arc exciton science Excellence Center and arc future low energy technology excellence center, combines platinum with liquid gallium. The melting point of liquid gallium is only 29.8 ° C, which is equivalent to the room temperature in hot days. When combined with gallium, platinum becomes soluble. In other words, it will melt, and there is no need to ignite a powerful industrial furnace.

For this mechanism, treatment at high temperature is required only in the initial stage, that is, when platinum is dissolved in gallium to form a catalytic system. Even so, it only works for oneortwo hours at a temperature of about 300 ° C, which is far from the continuous high temperature often required in industrial scale chemical engineering.

To create an effective catalyst, researchers need to use a platinum to gallium ratio of less than 0.0001. Most notably, the resulting system proved to be more than 1000 times more efficient than its solid-state rivals, which require about 10% of expensive platinum to function.

The advantage goes beyond that, because it is a liquid based system, and it is more reliable. The solid-state catalytic system will eventually block and stop working. This is not a problem here. Like a waterscape with a built-in fountain, the liquid mechanism constantly refreshes itself, self adjusts its effectiveness for a long time, and prevents the catalytic system from accumulating on the surface like scum in a pond.