Centuries ago, alchemists tried to convert lead into gold. Although they have not succeeded, the concept of extracting precious resources from rich resources is still attractive Scientists at the Northwest Pacific National Laboratory (PNNL) of the U.S. Department of energy are working with industry to test a method to extract important minerals such as lithium from various water sources using magnetic nanoparticles

Lithium is an essential component of many electronic and energy technologies, including light lithium-ion batteries that power mobile phones and electric vehicles. By 2028, the global lithium market is expected to reach US $8.2 billion, but there is little lithium produced in the United States.

PNNL's patent pending technology not only has the potential to provide the United States with an opportunity to produce more of its own lithium and other key materials, but it also provides a faster and cheaper method. PNNL is developing magnetic nanoparticles surrounded by an adsorbent shell that can adsorb lithium and other metals in water related to various industrial processes.

These sources may include water from geothermal power stations, known as geothermal brine, or water extracted from the ground during oil or gas production. These particles can also be used in the sewage of seawater desalination plants, or even directly from seawater. Once these tiny iron-based particles are added to the water, lithium is attracted from the water and combined with them. Then, with the help of the magnet, the nanoparticles can be collected in just a few minutes, and lithium is "free riding", no longer suspended in the liquid and can be easily extracted. After lithium is extracted, the recharged nanoparticles can be used again.

This technology provides a promising alternative to traditional extraction methods, that is, pumping groundwater into large and expensive evaporation tanks. These processes may take months or even years and affect groundwater management in arid areas where these methods are mainly deployed.

Although the PNNL process started working immediately, today's process is a bit like waiting for the water of a pot of lemonade to evaporate, hoping to recover the powdery mixture precipitated at the bottom. If the technology is deployed in geothermal power plants, the value of recovered lithium may increase the cost-effectiveness of this form of renewable energy, which uses water to capture heat deep below the earth's surface and then convert it into electricity.

PNNL is working with Moselle technologies to further develop this technology, which has been licensed and plans to pilot it in several places.

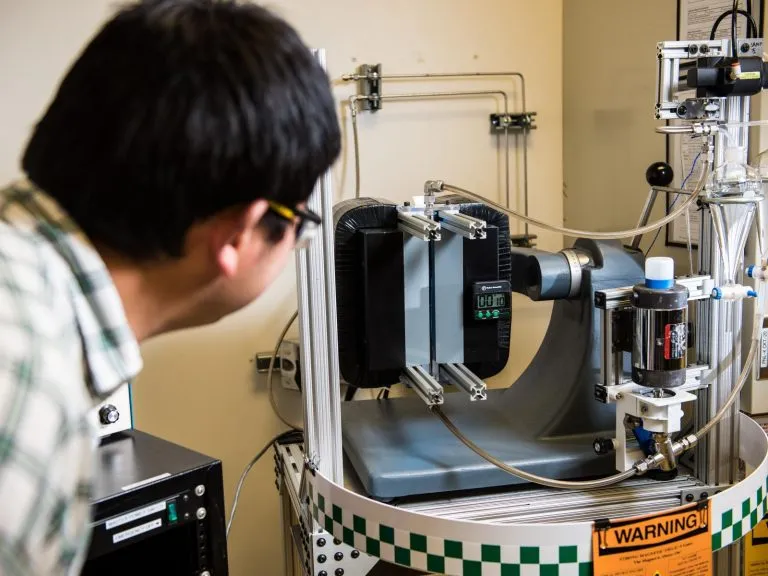

This work and follow-up activities are good examples of how national laboratories can work with commercial entities to transform laboratory research into real-world solutions. For example, PNNL researchers are conducting long-term testing of magnetic separator systems for possible use in oil and gas production processes, which can create an additional source of revenue to offset production costs.

In addition to Moselle, they are working with other business partners to evaluate the use of the technology in lithium resources in Nevada and Canada.

Finally, focusing on a series of different applications, PNNL researchers are customizing the shell of nanoparticles to specifically target other commercially valuable and strategic elements and minerals used in energy technology, medical imaging equipment, electronic products and so on.

For example, they are working with Moselle and geo40 to explore the possibility of extracting cesium and antimony from geothermal brine at a geothermal plant in New Zealand.

PNNL's new approach is really amazing. It offers the hope of extracting key minerals in a fast and cost-effective manner. And innovations like this may be worth the money.