"Signal building, train d805 applied to pass the washing warehouse..." "received, the washing equipment is in good condition, and the washing signal has been opened." At 19:30 on May 12, a green painted "Hulk" EMU train slowly pulled its long body to the washing shed in the passenger depot of Lanzhou depot of China Railway Lanzhou Bureau Group Co., Ltd.

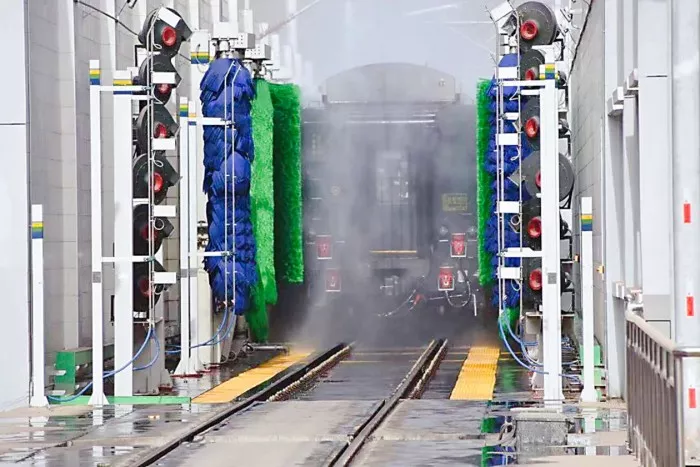

Then, the sensing device triggered the spray system and brush system, the side washing group, oblique washing group and skirt washing group. All components coordinated and quickly rotated to clean the yellowing train skin. In less than 10 minutes, a brand-new and shiny "Hulk" appeared immediately.

Gansu, located in the Loess Plateau, has a dry climate all year round, especially in spring, with heavy wind and sand and much dust. During the day, the "Hulk" EMU of Fuxing sped on the railway line to transport passengers from south to north. After the day's task, a layer of "earth color" armor was worn on the outside of the car body. At night, "Hulk" drove to the overhaul depot of Lanzhou depot, received comprehensive "skin care", maintenance and renovation, and embarked on a new journey in the early morning of the next day.

Lanzhou dynamic assembly workshop of Lanzhou rolling stock depot undertakes the maintenance and operation of 16 sets of "Hulk" power centralized EMUs. In recent years, with Lanzhou bureau group company vigorously promoting technological innovation and infrastructure upgrading, the first fully automatic washing warehouse built in 2021 has been officially put into use. The newly-built washing shed is 36m long and 6m wide, and is equipped with mechanical washing system, spraying system, control system, water supply system, water circulation system, positioning detection system, speed measurement system and monitoring system. The distance between the brush of each washing arm and the outer skin of the cleaning train can be flexibly adjusted. A set of automatic cleaning equipment can automatically complete the cleaning and drying of both sides of the vehicle body, side top arc surface and side lower skirt.

"Before the establishment of the washing warehouse, a group of trains needed 6-7 people to wash for 1 hour, which took a long time and consumed a lot of water. Now, the fully automatic washing, only one person can complete all the cleaning work, and a group of trains only needed 10 minutes, which greatly improved the efficiency of washing and reduced the labor intensity." Wang Baoliang, deputy director of the dynamic assembly workshop of Lanzhou rolling stock depot, said.

It is understood that the washing depot of Lanzhou depot needs to wash 7 sets of "Hulk" EMUs every day, and also wash about 8 sets of ordinary speed buses. Since it was put into use, more than 2500 motor buses have been cleaned, providing high-quality services and guarantee for passengers to travel comfortably.