Perovskite is a series of materials. At present, it is the main competitor to replace the widely used silicon-based solar photovoltaic. They are expected to be used to make lighter and thinner battery panels, which can be manufactured in ultra-high production at room temperature, rather than at high temperatures of several Baidu, and are easier and cheaper to transport and install. However, transforming these materials from small laboratory experiments into products that can be manufactured competitively has been a protracted struggle.

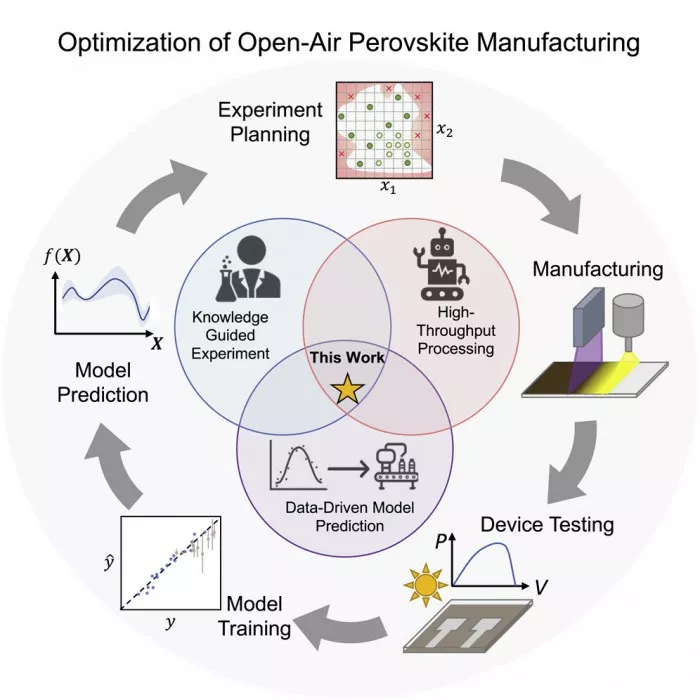

The production of perovskite based solar cells requires simultaneous optimization of at least a dozen variables, even in a specific manufacturing method among many possibilities. However, a new system based on new machine learning methods can accelerate the development of optimized production methods and help the next generation of solar power generation become a reality.

The system was developed by researchers at MIT and Stanford University in the past few years, making it possible to integrate previous experimental data and information based on the personal observations of experienced workers into the machine learning process. This makes the results more accurate and has led to the manufacture of perovskite batteries with an energy conversion efficiency of 18.5%, which is a competitive level for today's market.

The study was recently published in Joule00130-1?_ returnURL=https%3A%2F%2Flinkinghub. elsevier. Com% 2ffretrieve% 2fpii% 2fs254243512201301% 3fshowall% 3dtrue), the authors of the paper are Tonio buonasisi, a professor of mechanical engineering at MIT, Reinhold dauskardt, a professor of materials science and engineering at Stanford University, Liu Zhe, a recent research assistant at MIT, Nicholas Rolston, a doctoral graduate of Stanford University, and three others.

Perovskite is a group of layered crystalline compounds, which is determined by the atomic configuration in its lattice. There are thousands of such possible compounds and many different manufacturing methods. Although spin coating technology is used in the development of most laboratory scale perovskite materials, it is not practical for larger-scale manufacturing. Therefore, companies and laboratories around the world have been looking for ways to convert these laboratory materials into practical and manufacturable products.

"There's always a big challenge when you try to take a lab scale process and move it to something like a startup or manufacturing line," said Rolston, now an associate professor at Arizona State University The team studied a process they thought had the most potential, a method called rapid jet plasma processing, or RSPP.

The manufacturing process will involve a moving roll to roll surface, or a series of plates. When the plates roll, the precursor solution of peroxide compound will be sprayed or inkjet on it. Then the material will enter the curing phase, providing fast and continuous output, "which is higher than any other photovoltaic technology," Rolston said.

"The real breakthrough of this platform is that it will enable us to expand in a way that other materials cannot do. Even materials like silicon need a longer time frame because they have to be processed. And you can think of it as more like painting," he added

In this process, at least a dozen variables may affect the results, some of which are easier to control than others. These variables include the composition of the starting material, temperature, humidity, the speed of the processing path, the distance of the nozzle used to spray the material onto the substrate, and the method of curing the material. Many of these factors can affect each other. If the processing process is in the open air, the humidity, for example, may be uncontrollable. It is impossible to evaluate all possible combinations of these variables through experiments, so machine learning is needed to help guide the experimental process.

However, although most machine learning systems use raw data, such as the measurement of the electrical and other properties of the test sample, they usually do not incorporate human experience, such as the qualitative observation of the visual and other properties of the test sample by the experimenter, or the information of other experiments reported by other researchers. Therefore, the team found a way to incorporate this external information into the machine learning model, using probability coefficients based on a mathematical technique called Bayesian optimization.

Using the system, he said, "with a model from experimental data, we can find trends that we couldn't see before". For example, they initially encountered difficulties in adjusting for uncontrolled changes in humidity in the environment. But the model showed them that "for example, we can overcome our humidity challenge by changing the temperature and changing some other knobs".

The system now allows experimenters to guide their process more quickly in order to optimize for a specific set of conditions or desired results. In their experiments, the team focused on optimizing power output, but the system can also be used to incorporate other criteria such as cost and durability. Buonassisi said members of the team are continuing their efforts.

The U.S. Department of energy, which sponsored the work, encouraged scientists to commercialize the technology, which is currently focusing on technology transfer to existing perovskite manufacturers. "We are now in contact with the company, and the code they developed has been provided free of charge through an open source server. It is now on GitHub, anyone can download it and anyone can run it. We are happy to help the company start using our code," buonassisi said

Liu zhe said that several companies are preparing to produce perovskite based solar panels, although they are still studying the details of how to produce them. He said that the companies there have not carried out large-scale production, but start with small and high-value applications, such as building integrated solar tiles, in which appearance is very important. He said that three of these companies "are producing one meter by two meter rectangular modules (equivalent to the most common solar panels today) within two years as planned or driven by investors".

"The problem is that they have not reached a consensus on which manufacturing technology to use," Liu said. He said that the RSPP method developed by Stanford University "still has a great opportunity" to be competitive. Moreover, the machine learning system developed by the team can prove to be very important in guiding the optimization of any process used in the end.

"The main goal is to speed up the process, so it takes less time, less experiments and less human time to develop something that can be used immediately and provide it to industry for free," he said

Ted Sargent, a professor at the University of Toronto, said: "the existing work on machine learning driven perovskite photovoltaic manufacturing mainly focuses on spin coating, which is a laboratory scale technology." he was not involved in this work. He said the work demonstrated "a workflow that can easily adapt to the deposition technology that dominates the thin film industry. Only a few groups have both engineering and computing expertise to promote such progress". Sargen added that this approach "could be an exciting advance for the manufacture of a wider family of materials", including LEDs, other photovoltaic technologies and graphene. "In short, any industry that uses some form of vapor or vacuum deposition."