In the Global Health Assessment 2019 report, published by the World Health Organization in December 2020, heart disease has been the leading cause of death globally for the past 20 years, and more people are dying from heart disease than ever before. Since 2000, the number of heart disease deaths has increased by more than 2 million, rising to nearly 9 million in 2019.

▲ Photo from: The Guardian Nigeria

Many of these patients with serious conditions require a heart transplant, yet this wait is always too long and it is not uncommon to wait more than six months or even before the time of life runs out. This shows that we need more effective heart tissue replacement options.

In 2017, a team of researchers at ETH Zurich used 3D printing to create an artificial silicone heart that beats like an organ in a human body, but tests at the time showed it could last only 30 to 45 minutes of use.

▲Image from: ETH Zürich

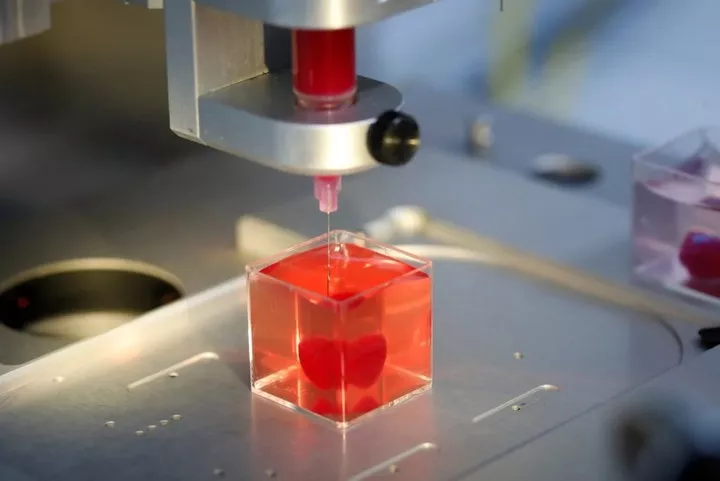

In 2019, researchers at Tel Aviv University in Israel succeeded in printing the first 3D heart using patient cells and biomaterials. This is a fully constructed heart that includes parts such as blood vessels and ventricles, but it is only the size of a rabbit's heart.

▲ Photo from: Tel Aviv University

The regenerative capacity of the heart itself is limited, and these artificial hearts, while bearing some fruit, do not mimic the highly structured structure and complex functions of the heart muscle and are naturally limited in their usefulness in restoring heart function.

Now, the Wyss Institute for Biologically Inspired Engineering at Harvard University and Jennifer Lewis's team at the Harvard School of Engineering and Applied Sciences (SEAS) have come together to develop a new set of heart engineering techniques.

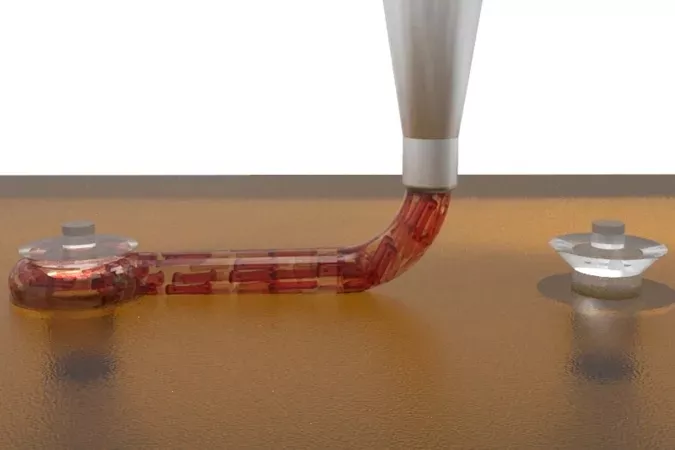

▲ Image from: Wyss Institute

This solution is a modification of Wyss' existing SWIFT bioprinting technology, built on a 3D bioprinting platform. The platform developed by the researchers has 1050 individual wells, each containing two microcolumns.

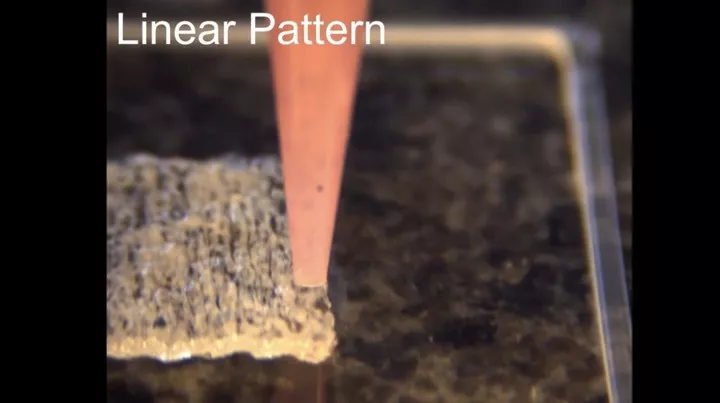

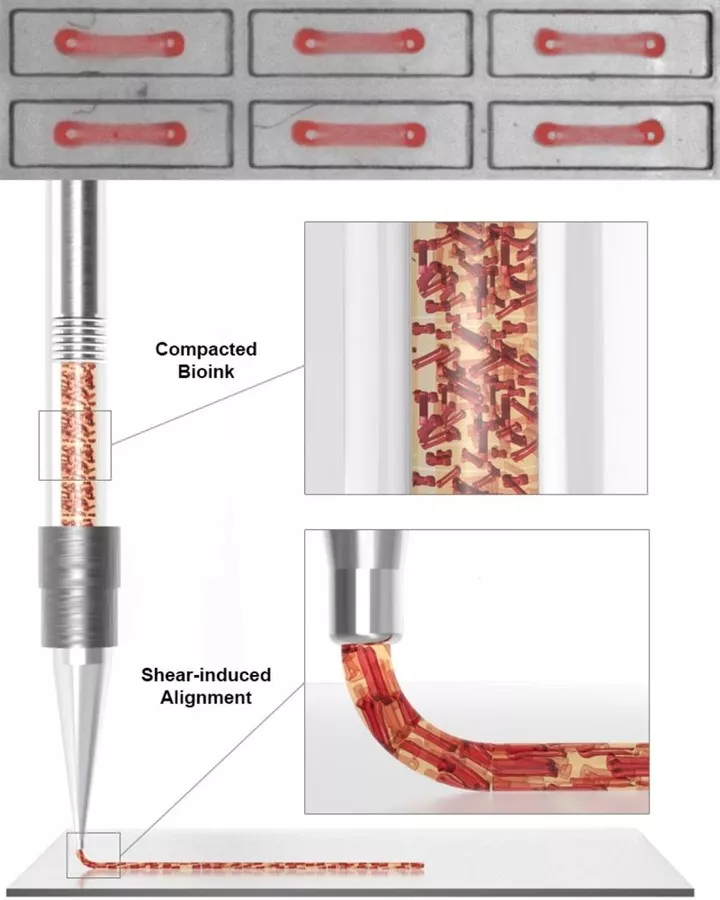

Artificially induced pluripotent stem cell-derived cardiomyocytes (hiPSCs-CMs) were used to form pre-assembled cardiac organ building blocks (OBBs), which were then removed from the micropillars and used as feedstock for the fabrication of dense bioinks, and further aligned during printing using the motion of the 3D printer head.

▲Image from: Wyss Institute

After trials, the researchers were able to print complex and variably aligned slices of heart tissue that were organized and functioned similarly to actual human heart muscle layers.

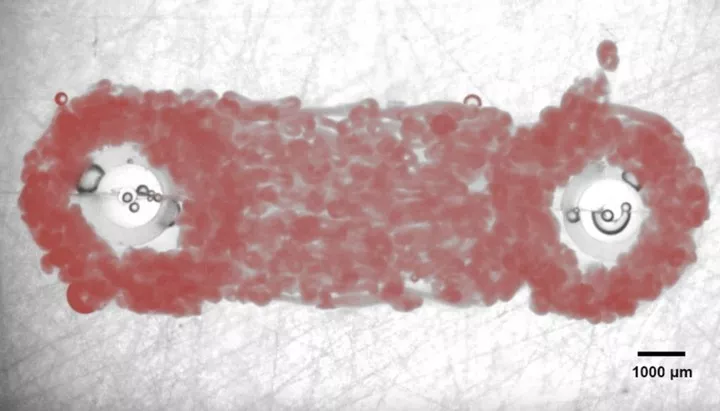

To test the contractile characteristics of the printed heart structure, the researchers also printed 'large filaments' connecting the two large columns, and measured that the contractile force and contraction speed produced by the filaments increased over 7 days, suggesting that the heart filaments continue to mature into true muscle-like filaments.

▲Image from: Wyss Institute

This also means that this technique can effectively mimic the arrangement of the cardiac contractile system throughout its hierarchy, from individual cells to thicker cardiac tissues consisting of multiple layers, and is essential for generating functional cardiac tissues for use in alternative treatments, as well as for generating more physiological disease models.

In the future, with the help of this technology, it may be possible to create highly structured heart muscle patches that match the specific areas where different patients have heart attacks. For example, custom-made patches could be used to repair patient-specific 'holes' in the hearts of newborns with congenital heart defects, and these patches could develop along with the child without having to be replaced as the child grows.

▲Image from: Wyss Institute

While there is still a long way to go before a fully functional and complete heart can be 3D printed, the creation of this technology is already a huge step forward and may not be far from the day when the difficulty of 'healing the heart' is removed.