*Researchers at the Federal Institute of Technology (EPFL) in Lausanne, Switzerland, demonstrated a light-based 3D printing method that is 30 times faster than traditional additive manufacturing *. Due to the use of light curing resin, objects that usually take 10 minutes to manufacture can be produced in 20 seconds.

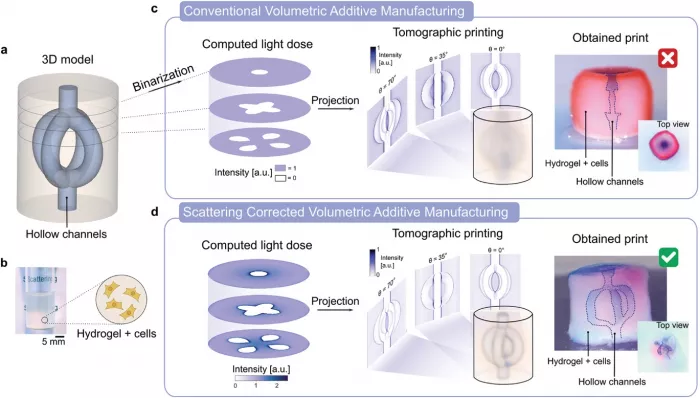

Ordinary 3D printing is to paste material on the substrate and allow (or cause) it to solidify, while the light-based process initiated by EPFL in 2017 adopts a completely different method and is much faster.

"We pour the resin into a container and rotate it. Then we irradiate the container at different angles and solidify the resin where the energy accumulated in the resin exceeds a certain level. This is a very accurate method that can produce objects at the same resolution as existing 3D printing technology," said Christophe Moser, a professor at the EPFL applied photon equipment laboratory

Making things in this way is very fast - it takes only a few seconds, not a few minutes. Another advantage is that users can print shapes with complex hollow parts without using the support structure of a tablet printer.

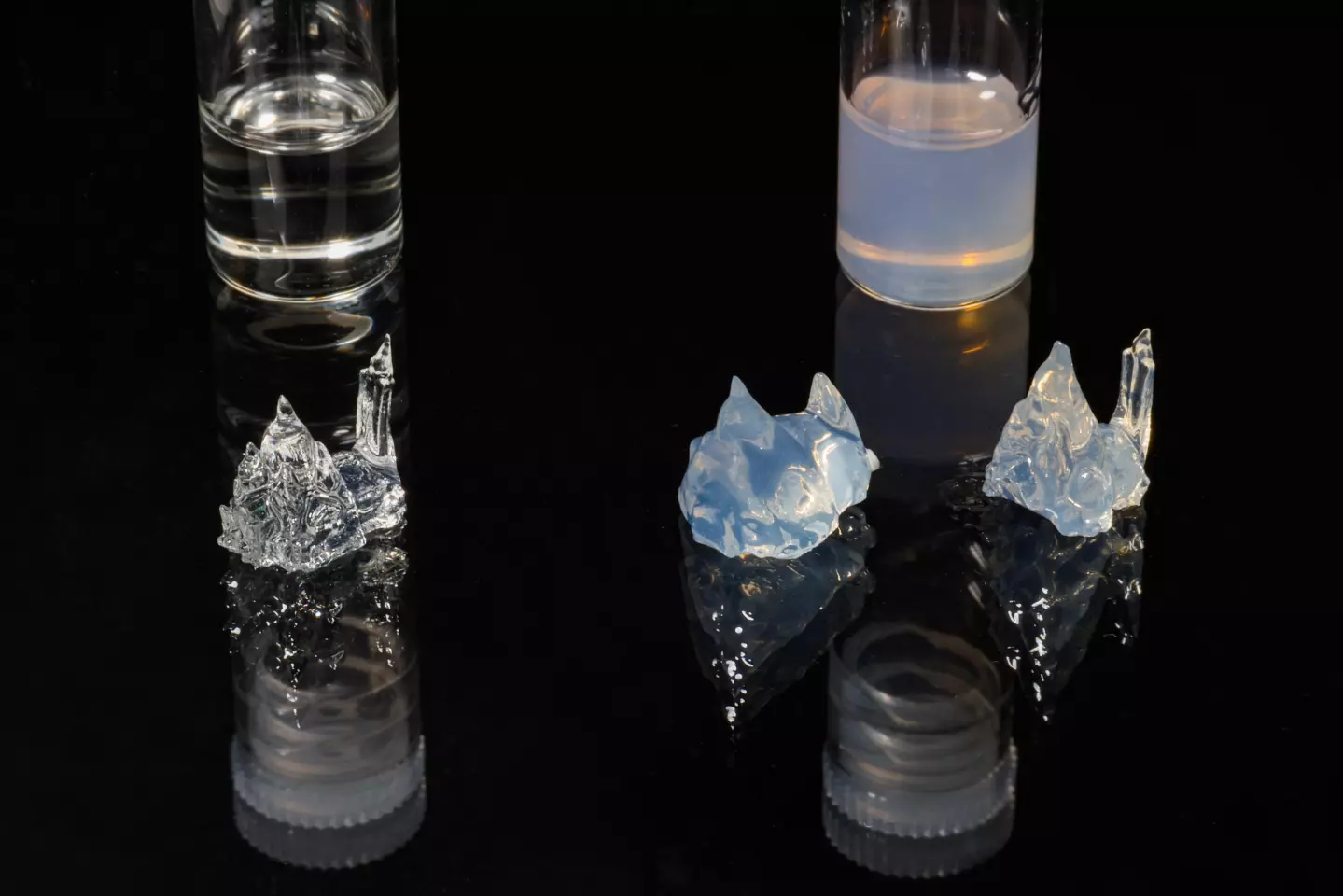

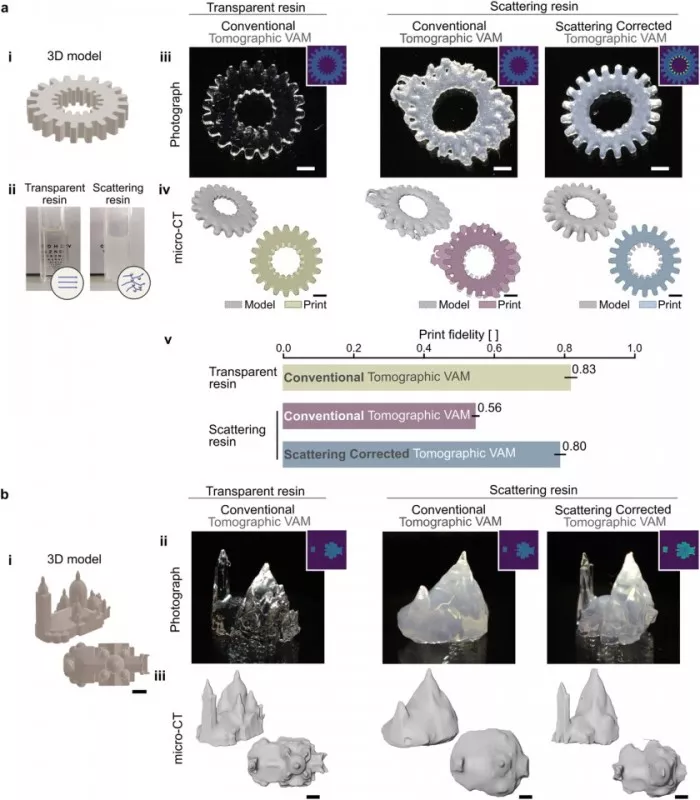

So far, the problem with this technology is that it can only use transparent resin - because anything with a little color, such as the opaque resin used to make artificial arteries in the biomedical industry, will bend and distort when light passes, resulting in a sharp decline in resolution and some printed objects that look quite sad.

But in a new study released this week, Moser and his team demonstrated a technique that allows the use of opaque resins to calculate the path of light through the resin by using a camera behind the resin. After analyzing the passing light, the team was able to create a distortion correction algorithm and apply it to print instructions while the machine was running so that the correct energy reached each point.

The team said that the resulting opaque resin printing is still very fast. The team produced a small print Yoda in about 20 seconds. Their resolution is almost the same as that of transparent resin, about one tenth of a millimeter. The team is now working to improve the resolution by 100 times, with the goal of micron accuracy.

The study was published in advanced science 》Open access in magazines.